Specification

- Brand: DESU

- Origin: Shanghai, China

- Width: 300-1400mm

- Barrier material: Recycled PET Plastic Sheets

- Processing methods: Lamination / Multilayer co-extrusion

- Thickness: 0.2-2.0mm

- Weight: 50-150kg/roll

- Shape: Roll/Sheet

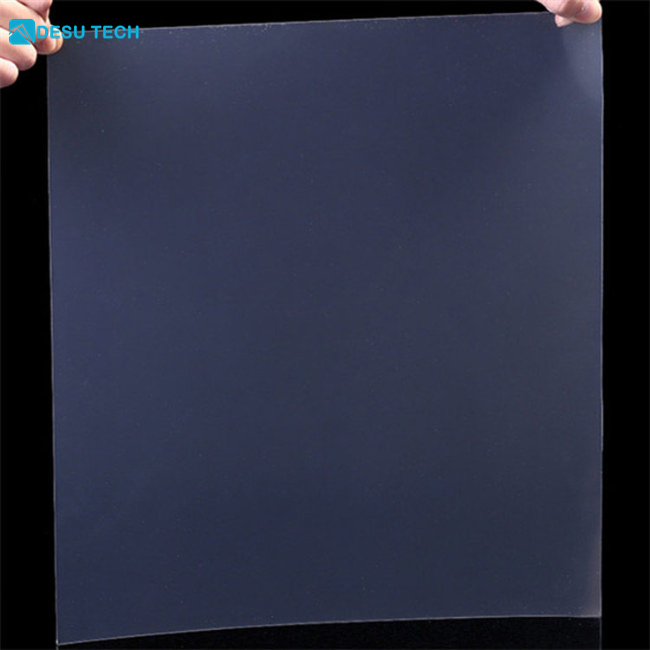

- Color: Transparent/Custom color

- Application: Bottles and Containers

- MOQ: 5tons

Product Introduction Of Recycled PET Plastic Sheets

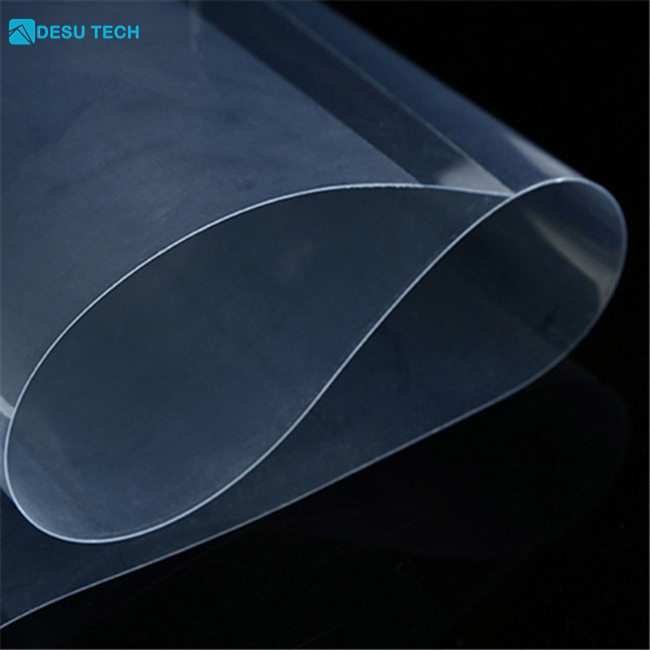

Recycled PET plastic sheets are a cutting-edge and sustainable alternative to traditional plastic sheets, offering a range of applications while contributing to environmental conservation. These sheets are manufactured from post-consumer PET plastic, predominantly sourced from recycled beverage bottles and packaging materials.

Key Features Of Recycled PET Plastic Sheets

1. Sustainability

- Utilizes post-consumer recycled PET, reducing dependence on virgin plastic.

- Contributes to waste reduction by repurposing plastic materials.

- Supports circular economy principles by extending the life cycle of plastics.

2. Environmental Benefits

- Lowers carbon footprint compared to sheets made from virgin materials.

- Decreases energy consumption and resource usage in production.

- Addresses plastic pollution by diverting plastic waste from landfills and oceans.

3. Versatility

- Available in various thicknesses and sizes to accommodate diverse applications.

- Suitable for various fields of product packaging.

- Customizable to meet specific requirements in terms of color and other properties.

4. Material Properties

- Retains key properties of PET plastic, including transparency and mechanical strength.

- Resistant to chemicals and moisture, ensuring durability in various environments.

- Potential for modification based on application-specific needs.

Product Application Of Recycled PET Plastic Sheets

Recycled PET (polyethylene terephthalate) plastic sheet can be used in a variety of applications in different industries due to its versatility and environmental friendliness.

1. Food packaging

Recycled PET sheets are often used to make food packaging materials such as clamshells, trays and containers.

2. Beverage packaging

Recycled PET is widely used in the production of beverage bottles, reducing the environmental impact compared to virgin PET.

3. Medical Trays and Containers

Recycled PET is used to produce medical trays and containers, providing a sterile and lightweight solution.

4. Electronic device packaging

Recycled PET sheets can be used to make electronic device packaging.

5. Toy product packaging

Recycled PET is used to manufacture environmentally friendly toys and product packaging.

6. Clothing and Fabrics

Recycled PET can be converted into fibers used in the textile industry to make eco-friendly clothing, bags, and other fabric products.

Product Processing Of Recycled PET Plastic Sheets

Processing recycled PET (polyethylene terephthalate) plastic sheets involves several key steps to transform post-consumer or post-industrial PET waste into usable sheets. Here’s an overview of the typical product processing steps:

1. Collection and Sorting

- Collection: Gather post-consumer or post-industrial PET plastic waste from various sources. This can include used beverage bottles, food containers, and other PET products.

- Sorting: Separate PET from other types of plastics using automated or manual sorting methods. Sorting is crucial to ensure the purity of the recycled PET.

2. Cleaning

- Shredding: The collected PET is shredded into smaller pieces. This increases the surface area and aids in subsequent processing steps.

- Washing: Remove contaminants and impurities through a washing process. This step may involve multiple stages, including hot washing and chemical washing.

3. Melting and Extrusion

- Melting: The cleaned and shredded PET flakes are melted to form a molten polymer.

- Extrusion: The molten PET is then extruded through a die to create a continuous sheet. This sheet can be of varying thickness depending on the intended application.

4. Cooling and Solidification

- Cooling: The extruded PET sheet is rapidly cooled to solidify it into a stable form. Controlled cooling helps in achieving the desired mechanical properties of the sheet.

5. Cutting and Forming

- Cutting: The solidified PET sheet is cut into the desired size and shape.

- Forming: In some cases, additional forming processes, such as thermoforming or vacuum forming, may be employed to shape the PET sheets into specific products or packaging.

6. Quality Control

- Testing: Conduct quality control tests to ensure that the recycled PET plastic sheets meet specified standards. This may include tests for thickness, strength, transparency, and other relevant properties.

- Sorting (Optional): Further sorting may be done to eliminate any defective sheets or those that do not meet quality standards.

It’s important to note that the processing steps can vary based on the specific equipment and technologies used by different manufacturers. Additionally, advancements in recycling technologies may lead to more efficient and sustainable methods in the future.