What is the lamination process?

Lamination refers to a transparent plastic film that is attached to the surface of the object by hot pressing to protect and increase the gloss. The product has a good waterproof and oil-proof effect after lamination.

Why choose PE protective film?

PE (polyethylene) film is colorless, odorless, non-toxic, odorless and translucent. It has excellent mechanical strength and dielectric properties, and has moisture resistance in humid environments. It can withstand low temperature to minus 70°C, and it can still maintain flexibility and chemical stability in low temperature environments. react. Compared with other films of the same thickness, PE film has lower transparency and lower flexibility, and the biggest point is that it is environmentally friendly and non-toxic.

PE film can generally be divided into three types. 1. Low density polyethylene film (LDPE), 2. Medium density polyethylene (MDPE), 3. High density polyethylene (HDPE). It varies according to the manufacturing methods used by different manufacturers. Based on the above advantages and unique properties, PE film is widely used in many fields, such as food, medicine, daily chemical, industrial and other fields.

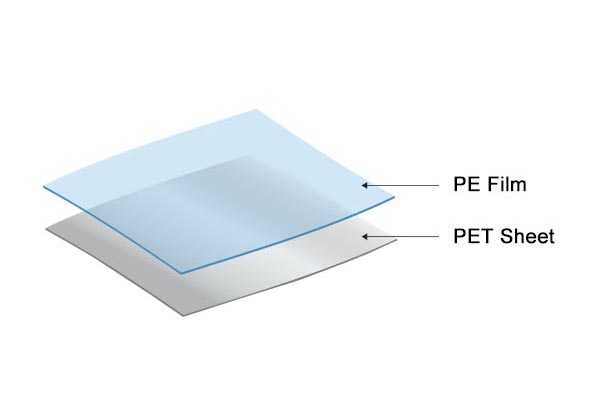

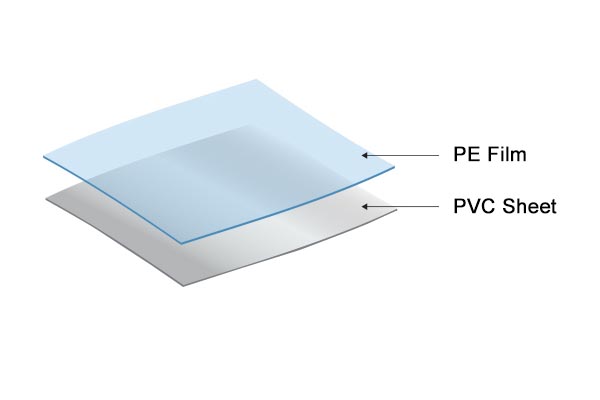

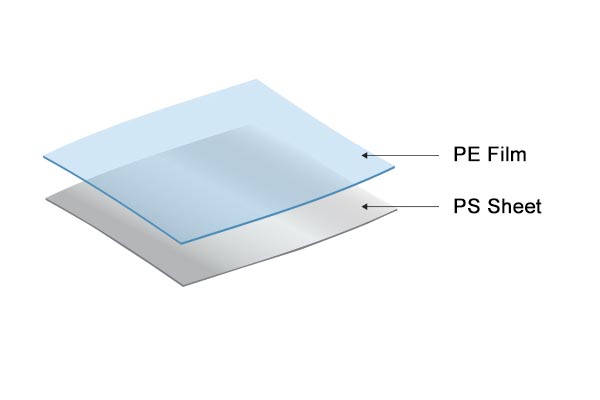

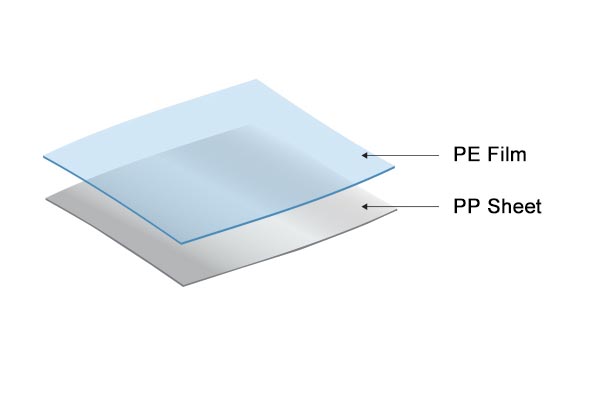

Desu Technology (Shanghai) Co., Ltd. produces a variety of composite plastic sheets, such as PET+PE, PS+PE, PP+PE, PVC+PE, which have good thermoforming properties.