What is EVOH?

EVOH is the most widely used material with high barrier properties. It is widely used in PP, PS, PET, and PVC materials. DESE TECH supplies PP+EVOH+PP, PET+EVOH+PET, PS+EVOH+PS, PVC+EVOH+PVC, PP+EVOH+PE, PS+EVOH+PE, PET+EVOH+PE, PVC+EVOH+PE And other composite plastic sheets.

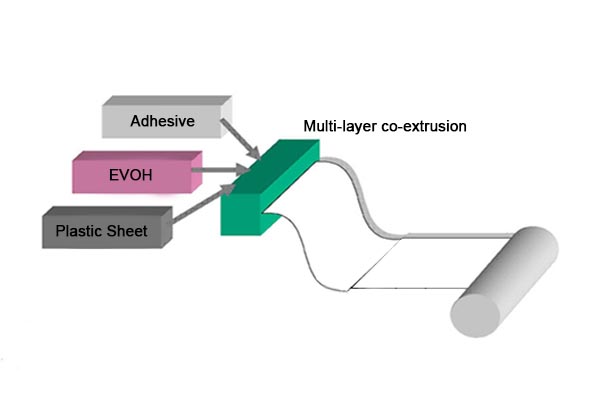

Multi-layer co-extrusion

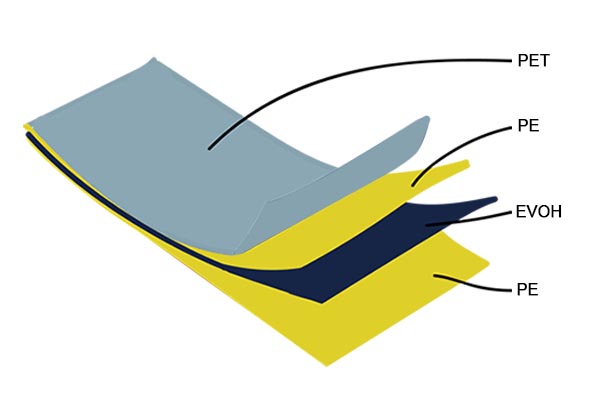

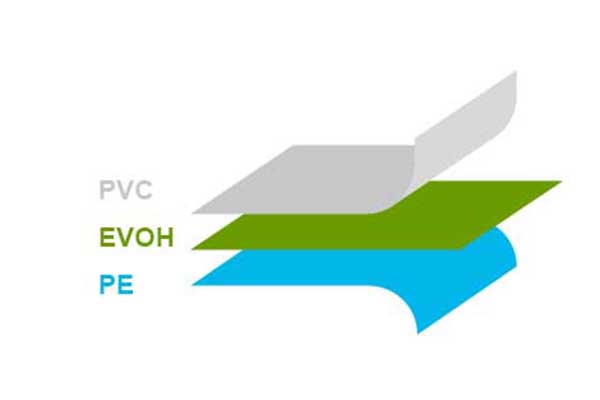

Multilayer co-extrusion technology is a traditional sheet extrusion production process. The biggest advantage of this process is that it has extremely high machining accuracy and can maximize the performance of the processed material. Especially in the processing of high-barrier multi-layer co-extruded sheets, it has unparalleled advantages.

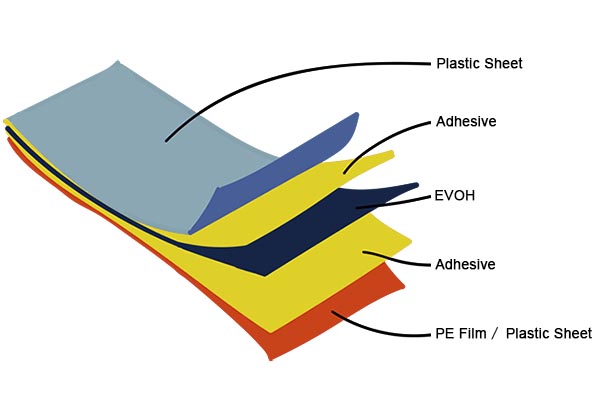

The structure of multi-layer co-extruded sheet can be divided into two categories, namely symmetrical structure (A/B/A) and asymmetrical structure (A/B/C). Most of them are 5, 7, 8, and 9 floors. The structural layer of the multi-layer co-extruded sheet consists of three types of functional layers: barrier layer, adhesive layer, and support layer.

Why Choose EVOH Plastic Sheet?

The notable feature of EVOH high barrier plastic sheet has excellent barrier properties to gases. In addition, it has excellent transparency, gloss, mechanical strength, stretchability, abrasion resistance, cold resistance and surface strength. In the packaging field, EVOH is made into a composite sheet intermediate barrier layer, which is used in all rigid and flexible packaging.

EVOH Plastic Sheet Uses

EVOH high barrier plastic sheets are mainly used in modified atmosphere preservation. Such as fruit packaging, cooked food, fresh meat, dairy products, flavorings, etc. It can also be used in non-food items, such as the packaging of chemicals and electronic components.

Specification

| Thickness | 0.18 ~ 2mm |

| Width | 300 ~ 1400mm |

| Support Layer Material | PTE/PP/PS/HIPS |

| Processing methods | Lamination / Multilayer co-extrusion |