Brief introduction of Lightweight PET plastic rolls

Lightweight PET plastic rolls are flexible sheets made from polyethylene terephthalate (PET) resin, a type of thermoplastic polymer known for its clarity, strength, and recyclability. These rolls are commonly used in various industries for packaging purposes due to their lightweight nature, durability, and versatility. PET plastic rolls are often preferred for their ability to provide barrier protection against moisture, gases, and odors, making them suitable for storing and transporting a wide range of products, including food, beverages, pharmaceuticals, and consumer goods. Additionally, PET plastic rolls are environmentally friendly as they are fully recyclable, contributing to sustainable packaging solutions.

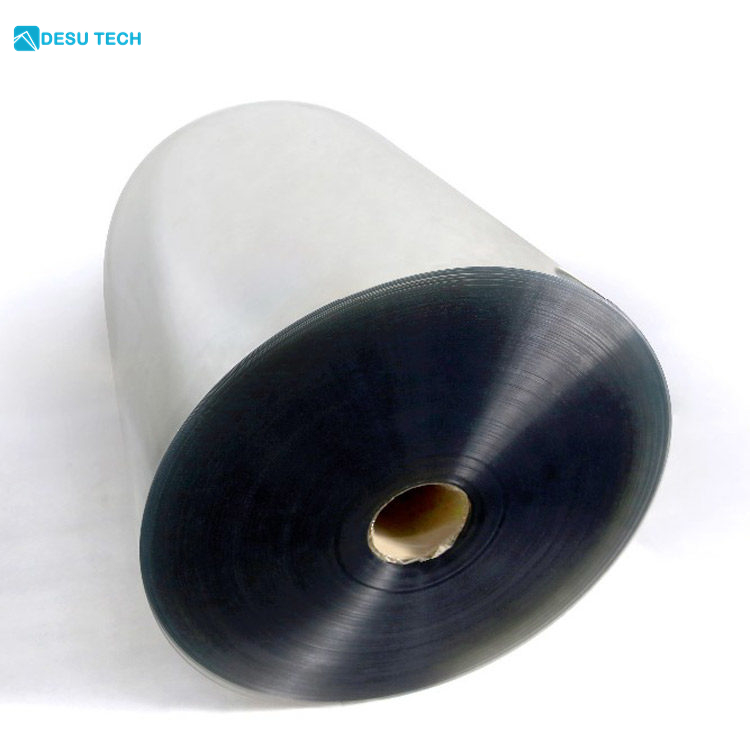

Specification

- Brand: DESU

- Origin: Shanghai, China

- Width: 300-1400mm

- Barrier material: Lightweight PET plastic rolls

- Processing methods: Lamination / Multilayer co-extrusion

- Thickness: 0.2 mm

- Weight: 50-150kg/roll

- Shape: Roll/Sheet

- Color: Transparent/Custom color

- MOQ: 5tons

Product advantages of Lightweight PET plastic rolls

Lightweight PET plastic rolls provide a combination of performance, sustainability, and cost-effectiveness, making them an attractive choice for a wide range of packaging needs across industries.

1. Lightweight

PET plastic rolls are lightweight, which reduces transportation costs and energy consumption compared to heavier packaging materials. This lightweight nature also makes them easier to handle and manipulate during packaging processes.

2. Durable

Despite being lightweight, PET plastic rolls are durable and resistant to tearing, puncturing, and impact, ensuring the integrity of packaged products during storage and transportation.

3. Clarity

PET plastic rolls typically exhibit excellent clarity, allowing for high visibility of packaged products. This feature is particularly beneficial for retail packaging, where product presentation is essential for attracting customers.

4. Barrier Properties

PET plastic rolls provide excellent barrier properties, protecting packaged products from moisture, oxygen, UV light, and other environmental factors that could compromise their quality and shelf life.

5. Recyclability

PET plastic roll is fully recyclable, contributing to sustainability efforts by reducing waste and conserving resources. Recycled PET (rPET) can be used to manufacture new PET plastic products, promoting a circular economy and minimizing environmental impact.

6. Versatility

PET plastic rolls are versatile and can be easily customized to meet specific packaging requirements, including size, shape, thickness, and printing options. They are suitable for various packaging formats, such as pouches, bags, wraps, and sleeves.

7. Cost-Effectiveness

PET plastic rolls are cost-effective packaging solutions, offering a balance between performance and affordability. Their lightweight nature reduces shipping and handling costs, while their durability minimizes the risk of product damage and loss.

8. FDA Approval

PET plastic roll is approved by the Food and Drug Administration (FDA) for food contact applications, ensuring compliance with safety regulations for packaging food and beverage products.

Product application of Lightweight PET plastic rolls

1. Food Packaging: PET plastic rolls are extensively used for packaging food products such as snacks, confectionery items, baked goods, fresh produce, and beverages. Their barrier properties help preserve the freshness and flavor of the food while providing a transparent and attractive packaging option for consumers.

2. Beverage Bottles: PET plastic is a popular material for manufacturing beverage bottles for water, soft drinks, juices, and other liquid products. Lightweight PET plastic rolls are used to produce preforms, which are then blown into bottles using stretch blow molding techniques.

3. Personal Care Products: Lightweight PET plastic rolls are utilized for packaging personal care and hygiene products such as shampoos, conditioners, lotions, soaps, and cosmetics. Their durability and clarity enhance product visibility and consumer appeal on store shelves.

4. Pharmaceutical Packaging: PET plastic rolls are suitable for packaging pharmaceutical products, including tablets, capsules, syrups, and creams. Their excellent barrier properties help protect medications from moisture, light, and contamination, ensuring their effectiveness and safety.

5. Household Products: PET plastic rolls are used for packaging household products such as cleaning agents, detergents, air fresheners, and pet care items. Their lightweight and durable nature make them suitable for handling and storing a variety of household goods.

6. Industrial Packaging: PET plastic rolls find applications in industrial packaging for wrapping and protecting products during storage, shipping, and handling. They are used for packaging materials such as textiles, electronics, automotive parts, and industrial components.

7. Medical and Laboratory Applications: Lightweight PET plastic rolls are used in medical and laboratory settings for packaging and sterilizing medical devices, diagnostic kits, laboratory consumables, and other healthcare products.

8. Agricultural Packaging: PET plastic rolls are utilized for agricultural applications such as packaging seeds, fertilizers, pesticides, and horticultural products. Their barrier properties help protect agricultural inputs from moisture, pests, and environmental factors.

Lightweight PET plastic roll is a thermoplastic polymer known for its clarity, strength and recyclability. Due to their lightweight, durability and versatility, these rolls are commonly used for packaging purposes in various industries.

PET plastic rolls are often favored for their ability to provide barrier protection against moisture, gases and odors, making them suitable for storing and transporting a variety of products, including food, beverages, pharmaceuticals and consumer goods. Additionally, PET plastic rolls are fully recyclable and therefore environmentally friendly, contributing to a sustainable packaging solution.

Product parameter of Lightweight PET plastic rolls

| Product name | Lightweight PET Plastic Roll, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Production video of lightweight PET plastic rolls

The production and processing of PET (polyethylene terephthalate) plastic rolls is a multi-step process. The following are the general steps for producing and processing PET plastic rolls:

1. Raw material preparation: First, PET resin needs to be prepared as raw material. PET is a polymer that is usually available in pellet or block form.

2. Pretreatment: PET resin typically undergoes pretreatment steps, including drying to remove moisture and other impurities. This is an important step to ensure the quality of the final product.

3. Extrusion: In the extrusion process, the pretreated PET resin is heated to the melting temperature and extruded through an extruder into film or roll form. This is a critical step in forming the plastic roll.

4. Cooling: The extruded PET film needs to be cooled to solidify into the desired shape and thickness.

5. Cutting: The cooled PET film can be cut as needed to form roll products of the required size and length.

6. Rewinding: Cut PET plastic rolls can be rolled onto cores or reels for easy storage and transportation.

7. Packaging: Finally, PET plastic rolls are often packaged to protect them from contamination and damage while making storage and transportation easier.