Notes for processing PET plastic sheet rolls

When processing PET plastic sheet rolls, you need to pay attention to the following aspects:

1. Safety Measures

Before processing PET plastic sheet rolls, ensure that operators follow necessary safety measures, including wearing appropriate protective equipment such as gloves, goggles, and face shields to prevent accidental injury.

2. Temperature control

PET is very sensitive to temperature during processing. During extrusion, calendering or other processing, be sure to control the temperature of the heated area to avoid overheating or overcooling, which can affect quality and performance.

3. Drying

PET is very sensitive to moisture, so it is necessary to ensure that the humidity of the raw material is within an acceptable range before processing. The use of drying equipment can effectively remove moisture from raw materials and improve processing quality.

4. Extrusion control

If PET plastic sheet rolls are processed by extrusion, ensure that the operating parameters of the extruder (such as extrusion temperature, extrusion speed, etc.) are well controlled to ensure the uniformity and consistency of the product.

5. Cooling

During processing, ensure effective cooling of PET to prevent overheating and maintain the desired shape and size. This can be achieved by adjusting the cooling rollers or using a cooling fan.

6. Stretch Control

If a roll of PET plastic sheet needs to be stretched during processing, ensure that the stretching process is precisely controlled to meet the specifications of the final product.

7. Quality inspection

Establish a quality control system during the processing process to ensure that the product meets standards and customer requirements by testing parameters such as thickness, width, surface flatness, etc.

8. Recycling

After processing, consider recycling the waste to reduce environmental impact and comply with the principles of sustainable development.

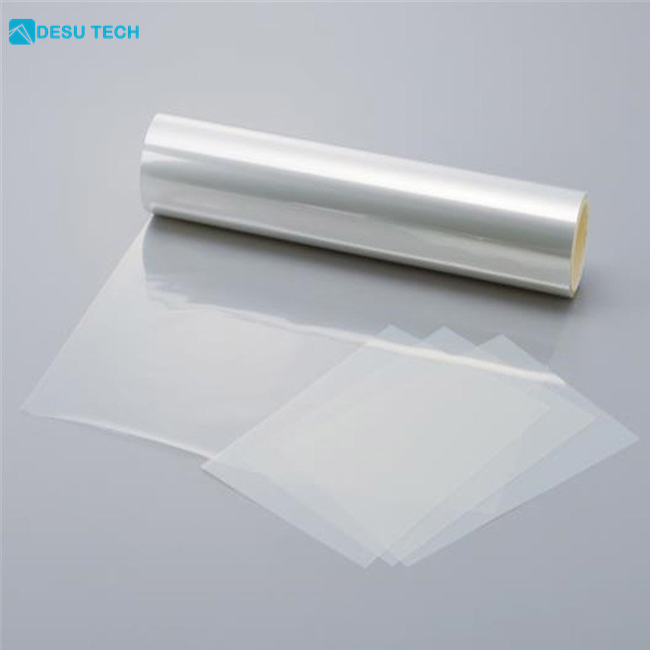

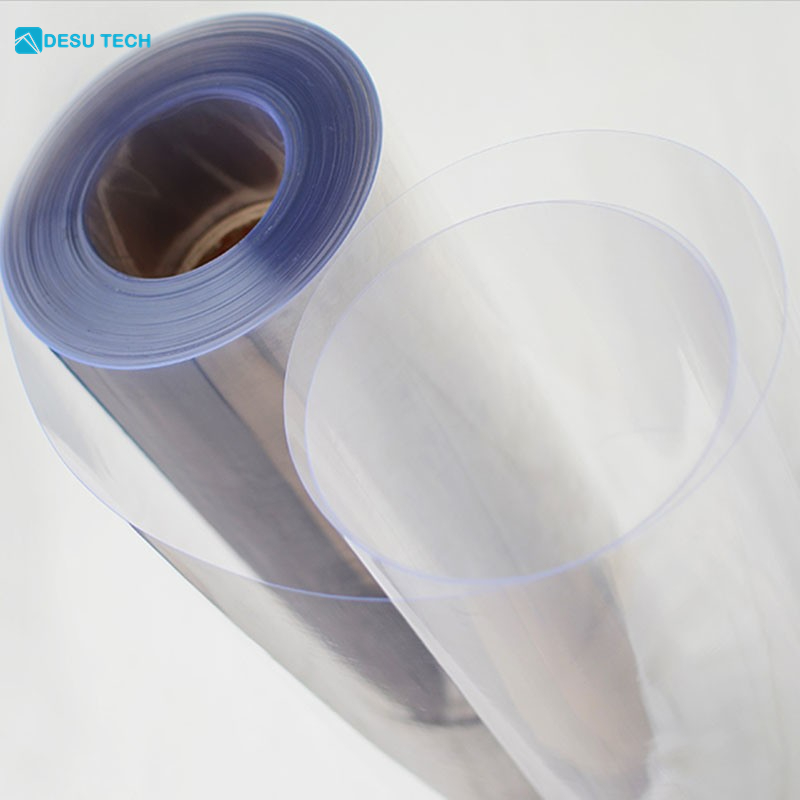

Brief introduction of PET plastic sheet rolls

PET plastic sheet rolls are a popular material for manufacturing clear and transparent cups. PET is chosen for its excellent clarity, lightweight nature, durability, and recyclability, making it an ideal choice for various beverage and food packaging applications.

Key Features

1. Transparency: Pet plastic roll provides a crystal-clear and transparent appearance, allowing the contents of the cup to be easily visible, enhancing product visibility and presentation.

2. Lightweight: Pet plastic roll is a lightweight material, making the cups easy to handle and transport. This feature is particularly beneficial for both manufacturers and end-users.

3. Durability: Pet plastic roll offers a high level of durability, ensuring that the cups can withstand typical handling during production, transportation, and consumer use.

4. Recyclability: Pet plastic roll is widely accepted in recycling streams, contributing to environmental sustainability. Cups made from PET can be recycled, reducing the environmental impact and promoting responsible disposal practices.

5. Customization Options: PET plastic rolls can be customized to meet specific requirements, such as different thicknesses, sizes, and even color options. This allows manufacturers to tailor the cups to their branding and product needs.

More Product