For the modern packaging industry, packaging environmental protection has become an inevitable trend in the development of the industry. In recent years, PVC packaging materials have gradually been replaced by more environmentally friendly materials in various fields, especially the food and daily chemical industries. Polyethylene terephthalate (PET) is highly favored by consumers and producers due to its excellent toughness, high strength, high transparency, and excellent environmental performance that it is recyclable and does not produce harmful gases when burned. More and more fast-moving consumer goods companies have issued sustainability declarations, stating that they will gradually stop using PVC materials and gradually switch to using PET materials. The conversion of blister cover sheets used in toothbrush packaging is a good practice.

But the particularity of PET material brings challenges to the automatic packaging production line. Compared with PVC material, PET material has high processing temperature, high melting point, and good flexibility. It has high requirements for punching dies of packaging machines, and the replacement frequency of punching dies is higher than that of PVC, which undoubtedly increases the production cost of enterprises. According to the analysis of the above problems, by optimizing the structure of PET sheet, improving the blister oil and upgrading the automatic packaging production line, the final packaging product with qualified effect is finally obtained.

Optimize the structure of PET sheet

Although PET has been used for blister packaging, but because it is a crystalline material, the glass transition temperature is high, and the molding temperature is high, ordinary polyester film can only obtain a heat shrinkage rate of less than 30% after special processing, which is difficult to process and shape. The impact resistance is poor, so it is necessary to improve its processing and molding properties through modification, blending and other methods to meet the requirements of toothbrush blister packaging.

APET (Amorphous Polyethylene Terephthalate) sheet is obtained by extruding a resin modified by isophthalic acid and diethylene glycol. APET is a thermoplastic environmentally friendly plastic product, which is widely used in blister packaging. Its waste can be recycled. The chemical elements contained in it are carbon, hydrogen, and oxygen like paper. It is a degradable plastic. APET has good folding resistance, and its specific gravity is 3.7% lower than that of general materials. It has high transparency, high strength, low temperature resistance, and can withstand tens of degrees below zero without embrittlement. Compared with ordinary PET, APET’s low temperature toughness (impact resistance and tear resistance) and heat resistance have been improved, and the appearance of the product has higher transparency.

PETG is a PET copolymer prepared by copolymerization and modification of glycols. PETG’s hardness, stiffness and toughness are better than ordinary PET sheets, and it also maintains toughness at low temperatures. The transparency of the product is higher, and it can be almost colorless. Its toughness is lower than that of APET, and its melting point is 20 ℃ lower than that of APET, but it has better plastic absorbing properties and is a degradable environmentally friendly material.

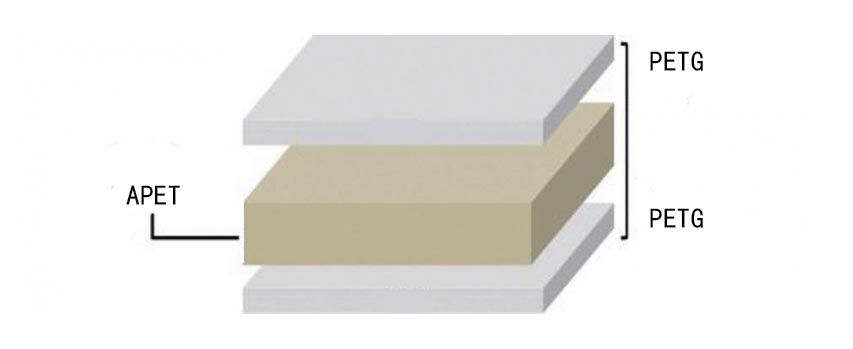

Combining the excellent characteristics of both APET and PETG, the PET blister sheet is made into a three-layer composite sheet (GAG). This three-layer composite sheet is produced by co-extrusion of the middle layer APET and the upper and lower layers of PETG raw materials in an appropriate proportion. PETG is easier to be cut, which can effectively increase the life of the die. Generally, in the case of cutting APET, the life of the cutter is only 150,000 times, and the cutter needs to be polished after it is worn. Because the gap between the upper and lower cutters must be kept within a certain range, the cutters are generally only allowed to be polished 5 times. After being made into a three-layer composite structure, the life of the die is effectively improved. In addition, a certain amount of recycled materials can be added to the middle layer to reduce costs.