We often see frozen meat, fresh-cut meat, deli and other products neatly placed in plastic trays in the fresh food section of supermarkets. These seemingly inconspicuous trays actually contain a lot of knowledge. Among them, a material called PP blister sheet is gradually becoming the mainstream choice for cold meat packaging in supermarkets.

PP blister sheet, as the name suggests, is a blister sheet made of polypropylene (PP) resin. PP resin is a thermoplastic with excellent properties and has the following characteristics:

- Non-toxic and environmentally friendly: PP resin does not contain any toxic substances and can be safely used for food packaging. In addition, PP resin can also be recycled and is an environmentally friendly material.

- Heat resistance and cold resistance: PP resin has good heat resistance and cold resistance and can be used in the temperature range of -20°C to 120°C. This enables PP blister sheets to adapt to the needs of different environments such as supermarket freezing and refrigeration.

- High strength and high rigidity: PP resin has high strength and rigidity and can withstand a certain amount of weight and pressure. This allows PP blister sheets to maintain good shape when packaging heavy items such as frozen meat.

- Easy to process: PP resin is easy to process into various shapes and can meet the packaging needs of different products.

- Recyclable: PP material is a recyclable material that can reduce the impact on the environment.

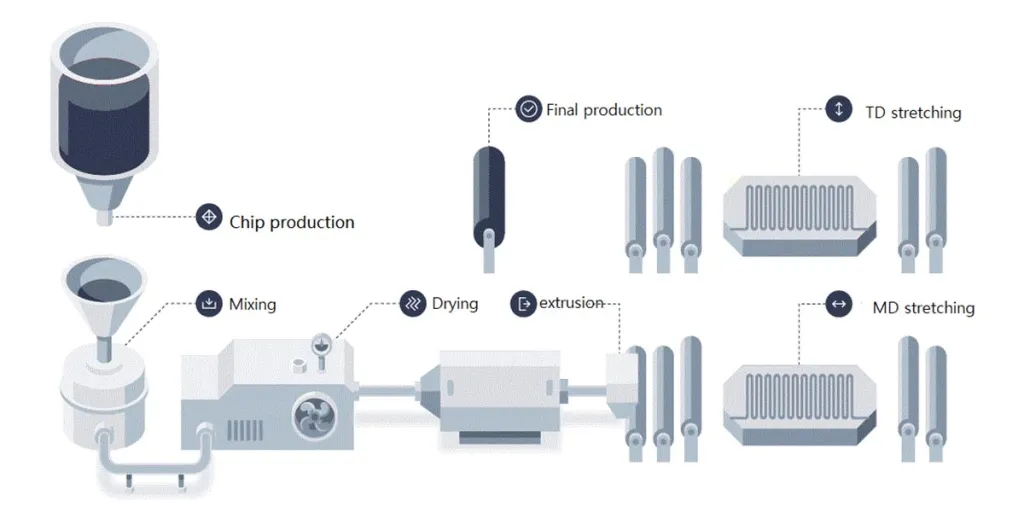

Production process of PP blister sheet

The production process of PP blister sheets mainly includes the following steps:

Raw material preparation: PP particles are dried, mixed and color matched.

Extrusion molding: The prepared PP mixture is plasticized into a melt through an extruder and extruded into sheets through a die.

Cooling and shaping: Cool and shape the PP sheet.

Cutting: Cut the PP sheet to the required size.

Inspection and packaging: Inspection and packaging of PP sheets.

Common specifications of PP blister sheets

PP thermoformed blister sheet for food packaging

Common specifications of PP blister sheets include the following:

Thickness: 0.2mm-2.0mm

Width: 300mm-850mm

Color: clear, Natural, Black, White, Color, Customized according to needs.

Length: customized according to customer needs

Application of PP blister sheets in cold meat packaging

Compared with traditional packaging materials, such as foam paper, cartons, etc., PP blister sheets have the following advantages:

- More hygienic: The surface of PP blister sheet is smooth, not easy to absorb bacteria and dirt, and easier to clean and disinfect.

- Keep meat fresh: The good barrier properties of PP blister sheets can prevent oxygen from entering the packaging, thereby delaying the oxidative deterioration of meat and maintaining the freshness of meat.

- Prevent leakage: PP blister sheet has good water resistance and oil resistance, which can prevent the juice and grease in meat from leaking and keep the packaging clean.

- More beautiful: PP blister sheets can be printed with patterns and text to make product packaging more beautiful and enhance product image.

- More environmentally friendly: PP blister sheets are recyclable and more environmentally friendly.

- Easy to transport: PP blister sheets have high strength and stiffness and can withstand heavy objects without breaking, so they are easy to transport.

Taking supermarket cold meat packaging as an example, PP blister sheets can replace traditional foam plastic trays. Although foam plastic pallets are cheap, they have the following problems:

- Not environmentally friendly: Foam plastic pallets are difficult to recycle and can cause environmental pollution.

- Unhygienic: The surface of foam plastic trays easily absorbs bacteria and dirt, which is unhygienic.

- Unsightly: The foam plastic tray has a crude appearance, which affects the product image.

PP blister sheets can solve these problems well. PP blister sheets are not only hygienic and environmentally friendly, but also beautiful in appearance, which can improve the quality of cold meat products. Supermarkets using PP blister sheets to package cold meat can bring the following benefits:

- Reduce food loss: The good barrier properties of PP blister sheets can extend the shelf life of food, thereby reducing food loss.

- Improve product image: PP blister sheets can improve the packaging grade of cold meat products, thereby improving the supermarket’s brand image.

- Reduce packaging costs: PP blister sheet is a relatively low-priced packaging material that can help supermarkets reduce packaging costs.

In addition to being used for cold meat packaging, PP blister sheets are also widely used in the following fields:

- Medical device packaging: PP blister medical device packaging boxes are used to hold medical devices. They have good sterilization performance and can ensure the health and safety of medical devices.

- Cosmetic packaging: PP blister cosmetic boxes are used to package cosmetics with exquisite appearance and can enhance product quality.

- Stationery packaging: PP blister stationery boxes are used to package stationery, which are lightweight, durable and easy to store.

- Industrial parts packaging: PP blister industrial parts trays are used to hold industrial parts, are dust-proof and moisture-proof, and are easy to transport.

PP blister sheets are gradually becoming the mainstream material for supermarket cold meat packaging due to their excellent performance and environmental protection advantages. If you are looking for a safer, environmentally friendly and economical cold meat packaging solution, PP blister sheets will be your best choice.