Conductive PET sheets and conductive HIPS sheets are both commonly used conductive plastic sheets, but they have some differences in performance, application and price. If we need to use conductive plastic trays for electronic parts, which conductive plastic sheet should we choose?

The difference between conductive PET sheets and HIPS sheets

Conductivity:

The conductivity of conductive PET sheets is generally better than that of conductive HIPS sheets. This means that conductive PET sheets have lower resistivity and can conduct electricity more efficiently.

Mechanical behavior:

Conductive PET sheets generally have higher mechanical strength and stiffness than conductive HIPS sheets. This means that conductive PET sheets are more wear-resistant, impact-resistant and can withstand greater loads.

Conductive HIPS sheets generally have better toughness and flexibility than conductive PET sheets. This means conductive HIPS sheets are easier to bend and shape.

Transparency:

PET is known for its excellent clarity and transparency, making it ideal for applications where visibility is important. HIPS may not provide the same level of transparency.

Cost:

Evaluate the cost of two materials, including raw material cost and processing cost. HIPS is generally more economical than PET, but specific pricing may vary based on factors such as availability and processing requirements.

How to choose a suitable conductive sheet?

Choosing between conductive PET sheet and conductive HIPS sheet depends on a variety of factors, including your specific application requirements, budget, and processing capabilities.

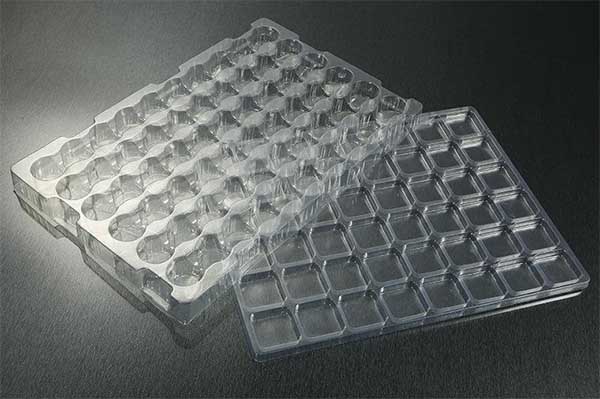

Conductive PET has excellent heat resistance, chemical resistance and mechanical strength. It generally has a high conductivity, provides stable electrical performance, and is suitable for applications requiring high conductivity. Such as electronic parts trays, electrostatic shielding covers, etc.

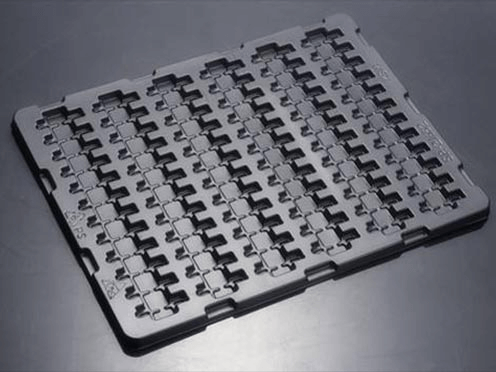

Conductive HIPS has higher impact resistance and formability, but its conductivity may be slightly lower than conductive PET. However, conductive HIPS is generally more cost-effective than conductive PET. It is suitable for applications that have high requirements on impact resistance and formability but loose requirements on conductivity, such as electrostatic shielding foam boxes, electronic product packaging, etc.

How to choose an electronic parts pallet?

If the electronic parts pallet needs to be used in high-temperature environments or in contact with chemicals, conductive PET may be a better choice because of its higher heat resistance and chemical stability.

If the main requirements for the pallet are impact resistance and formability, and the conductivity requirements are not particularly stringent, conductive HIPS may be a more cost-effective option.

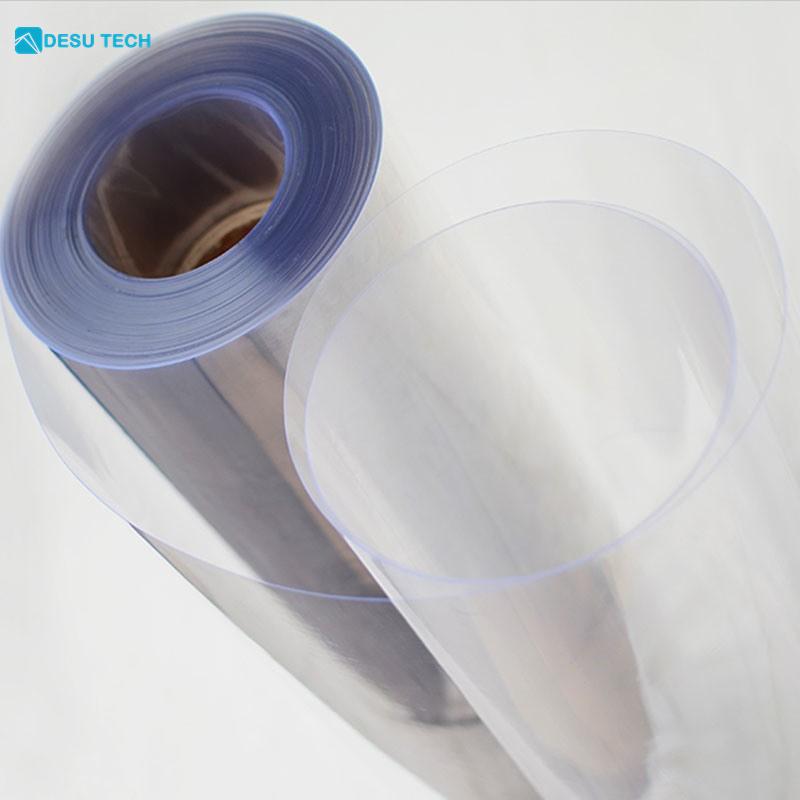

DESU conductive plastic sheet roll

Conductive PET sheet roll

- Width: 300-1400mm

- Barrier material: Conductive PET Plastic Sheet

- Processing methods: Lamination / Multilayer co-extrusion

- Thickness: 0.2 -2 mm

- Weight: 50-150kg/roll

Conductive HIPS sheet roll

- Width: 300-1400mm

- Thickness: 0.2-2.0mm

- Weight: 50-150kg/roll

- Color: Black

- Surface resistance: 10^4 to 10^6 Ω/sq

- Molding Process: Vacuum forming

- Application: Electronic product tray