Product Introduction of Blister Thermoforming PP Plastic Sheet

Blister thermoforming is a process used to form plastic sheets into various shapes to create packaging for various products. Polypropylene (PP) plastic sheets are commonly used in blister packaging for their durability, flexibility, and heat resistance.

Blister thermoforming is the process of creating plastic packaging by heating a flat sheet of plastic, usually polypropylene (PP), until it becomes pliable. The heated sheet is then placed over a mold and vacuum sealed around the mold edges to create a cavity. The plastic is cooled and hardened to form a rigid, custom-shaped container,The resulting packaging can be used to securely hold products in place, protect them from damage during shipping, and provide a clear view of the product inside.

Blister thermoforming pp plastic sheet is commonly used in the packaging of consumer goods such as electronics, pharmaceuticals and cosmetics, as well as items such as fruit, vegetables and snacks in the food industry.

Production technology of Blister Thermoforming PP Plastic Sheet

The production process of blister thermoforming PP plastic sheet includes the following steps:

1. Blister thermoforming PP plastic sheet Material preparation

Polypropylene (PP) resin pellets are commonly used as raw material for PP plastic sheets. The pellets are fed into an extruder, which melts the plastic and makes a sheet.

2. Blister thermoforming PP plastic sheet extrusion

Molten PP plastic is extruded through a die to form a flat plastic sheet of desired thickness. The sheet is then cooled and cut to the desired length.

3. Blister thermoforming PP plastic sheet trimming

Trim the edges of the sheet to remove any irregularities or imperfections.

4. Blister thermoforming PP plastic sheet board finishing

Sheets may undergo a variety of finishing processes, such as calendering to improve surface quality, embossing to add texture, or printing to add branding or labeling information.

5. Blister thermoforming PP plastic sheet storage

Finish sheets are stored in a climate-controlled environment to preserve their quality and prevent damage or degradation.

Overall, the production technology of blister thermoforming PP plastic sheet is a highly automated and continuous process that requires specialized equipment and expertise to ensure consistent quality and precision of the final product.

Product characteristics of Blister Thermoforming PP Plastic Sheet

Physical and Chemical Properties

| Melting temperature | 130°C |

| Typical injection temperature | 32-66 °C |

| Heat distortion temperature | 100°C (under 0.46 MPa pressure) |

| Tensile strength | 32 MPa |

| Flexural strength | 41 MPa |

| Specific gravity | 0.91 |

| Shrinkage rate | 1.5-2.0% |

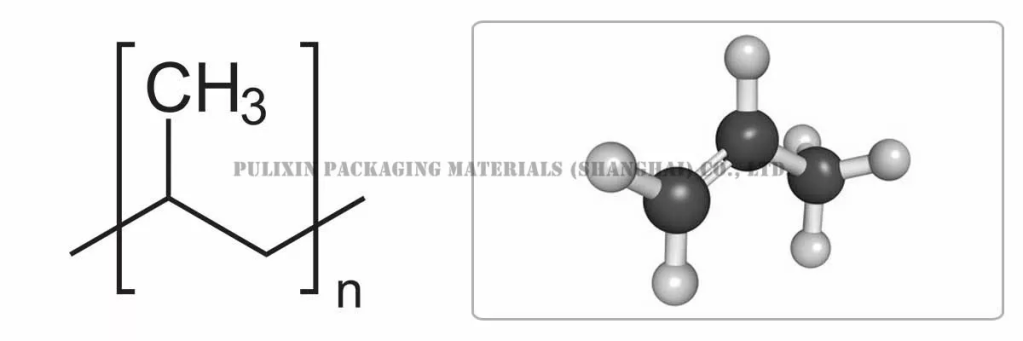

Chemical structure of PP material

Product Features of Blister Thermoforming PP Plastic Sheet

The product features of blister thermoforming PP plastic sheet include:

Customizable shape and size

Blister thermoforming PP plastic sheets can be molded into a wide range of shapes and sizes to fit the specific needs of a product.

Lightweight

Blister thermoforming PP plastic sheets are lightweight, making them an ideal material for packaging and transport applications where weight is a concern.

Durable

Blister thermoforming PP plastic sheets are resistant to impact, moisture, and chemicals, making them ideal for protecting products during shipping and storage.

Versatile

Thermoforming PP plastic sheets can be used for packaging a wide range of products, including electronics, cosmetics, pharmaceuticals, and food.

Cost-effective

Blister thermoforming PP plastic sheets offer a cost-effective packaging solution compared to other materials such as glass or metal.

Environmentally friendly

PP plastic sheets are recyclable and can be reprocessed into new products, reducing their impact on the environment.

Introduction Manufacturer of Blister Thermoforming PP Plastic Sheet

Desu is a professional manufacturer of PP, PET, PS plastic sheet. The company has passed ISO9001, SGS quality system certification test certificates.

We have an experienced professional team with 20 years of R&D, production and sales experience.

Our technicians and designers can provide you with help and help you customize products that are satisfactory.

Our professional quality control personnel are always before production. Monitor the production process.

Our products have been exported to many countries and regions in the world, especially in North America, Europe and Southeast Asia.

The high quality and integrity of our products have brought us a good reputation for long-term cooperation with customers.

We welcome customers from all over the world, we always provide customers with the best quality products, competitive prices and perfect service.

We look forward to establishing a reliable, good and trustworthy cooperative relationship with you in the near future and developing mutual benefits with you. Welcome to contact us.