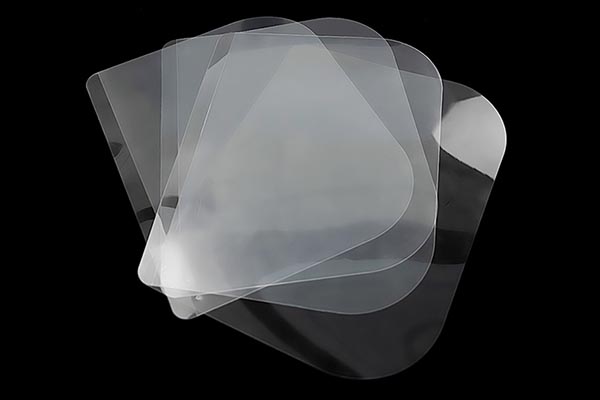

PC/PVC/PET plastic sheets are common plastic products in life, for example, they can be used as home appliance film panel surface stickers. According to the type, it can be divided into three types: PC, PVC, and PET. According to the surface of the material, it can be divided into frosted surface and smooth surface.

PC film materials

Whether it is physical or chemical properties of PC film materials, its comprehensive indicators are relatively good. It is also suitable for a wide range of ink types, and is the most commonly used plastic material for film panel surface stickers.

The PC film material has the distinction between the frosted surface and the glossy surface. PC matte surface material is often used in the control panel of outdoor industrial electronic products. The PC frosted film panel is used as the panel for operating the control system, and is mostly used outdoors, where you do not want to receive light interference. The surface of the PC matte film panel is diffusely reflective and does not produce bright reflections. At the same time, due to the disordered sand-like surface, it has the function of masking scratches.

In contrast, PC glossy materials do not have the characteristics of matte materials. However, the PC glossy material, after the wire brushing, the color will be more bright and dazzling, when the decorative requirements are strong and do not need to be used in outdoor scenes, it is a better choice to choose PC glossy material to make electrical control panel surface stickers . Or used in special real-world areas such as LCD liquid crystal display, it is more advantageous to use PC glossy material.

PVC film materials

The price of PVC film material is lower than that of other film materials, about one-half of that of PC film material. When producing large quantities of home appliance control panel products, if the PVC film material is used, the production cost can be reduced. At the same time, the ductility of the PVC film material is relatively good, and the three-dimensional concave-convex button bulge can be processed by cold pressing.

Glossy PVC sheet, with tape protection on both sides, is widely used to make decorative panels for household appliances or control film panels for household appliances industry. The PVC material with frosted surface is generally supplied in fixed-length sheets, not in coils.

Thickness specification/mm: 0.125, 0.175, 0.25, 0.5, 0.8

Features: acid and alkali resistance, insulation, high elasticity, white marks will appear on wrinkles, no embossing, not environmentally friendly.

PET film material

Features of PET material: high transparency, high hardness, high biaxial tensile strength, good toughness, high temperature resistance, corrosion resistance, and good aging resistance.

The price of PET film material is more expensive than the other two materials, and most of the performance of PET film material is similar to that of PC film material, so it is less used for control panel stickers than PC/PVC film material. However, in some special application scenarios, such as insulation, tensile and compressive resistance, solvent corrosion resistance, etc., when PC/PVC film materials cannot meet the requirements, PET plastic sheets need to be used.

PET film materials generally use a smooth and transparent surface, and also have a frosted surface, but the sand surface is very fine, similar to a polished surface layer. The polished surface is obtained on the PET surface, unlike PC, which is mechanically obtained from a sanded roller in a mechanical calendering process. This also determines that its surface is not as obvious as the sand surface of PC, but its price is about 3~5 times higher than that of sand surface PC.