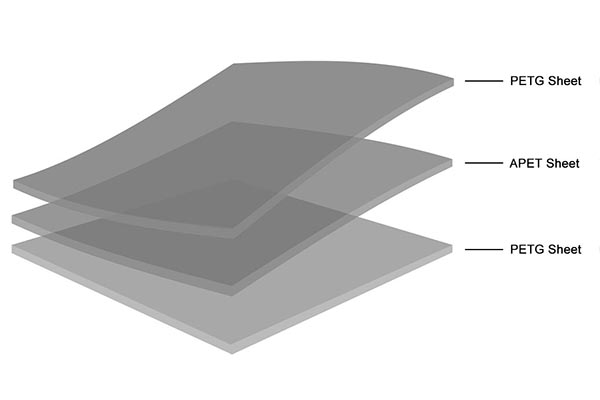

GAG plastic sheet is a three-layer composite plastic sheet, the upper, middle and lower layers are PETG–APET–PETG respectively. It has all the properties of PETA sheet, no corona treatment is required during printing, and ordinary ink can be used. There are various bonding methods: general solvent, general adhesive, friction bonding, high frequency bonding, ultrasonic bonding, mechanical bonding (screw, nail).

GAG plastic sheet is a kind of PET sheet, and it is also a widely used sheet in our life. GAG sheet is a kind of composite sheet, which has many advantages and is widely used. GAG plastic sheet has good transparency, the transparency can reach more than 90%, and the texture is good. It is suitable for making blister packaging products that require high transparency. Widely used in stationery, handicrafts, toys and gifts, food, cosmetics, hardware and other industries.

GAG Plastic Sheet Production

Generally, two extruders or three extruders are used to produce GAG plastic sheets. The extruders used in our DESU plastic sheet production workshop, combined with exquisite manufacturing processes, produce GAG sheets with good flatness and no defects ( Such as crystal point, white point, black point), no vertical and horizontal lines on the surface.

The extruder includes single-screw extruder and twin-screw extruder. The quality of GAG sheets produced by different models will be different. The main difference is the transparency of GAG sheets. Generally, a single-screw extruder is used for the production of high-gloss GAG sheets, and a twin-screw extruder is recommended for the production of color films, which can reduce the overall cost.

GAG Plastic Sheet Blister Characteristics

GAG is a three-layer composite sheet. The three-layer composite sheet produced by co-extrusion of the middle layer of APET and the upper and lower layers of PETG raw materials in an appropriate proportion is especially suitable for packaging boxes that need to be bonded by high-frequency heat sealing and glue. Its advantages are as follows:

- Good transparency, the transparency can reach more than 90%, the texture is good, and it is suitable for products requiring high transparency.

- Excellent impact strength and rigidity, hard and durable material, suitable for high impact strength applications.

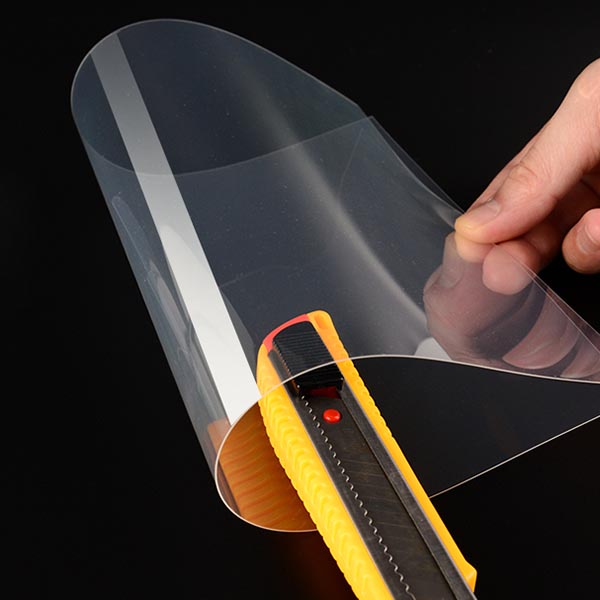

- Excellent workability, can use sawing, die cutting, drilling and laser cutting and other processing methods. It can also be processed by cold bending and hot bending, adhesion, welding and polishing, printing and painting. And cold bending does not whiten, and the appearance is bright.

- Good thermoformability, can be formed without preheating, high precision, and shrinkage rate of about 0.5%. Good deep formability, no cracking and uniform thickness.

- Environmental protection, recyclable and non-polluting to the environment.

- Excellent food hygiene, the material is PETG, which can meet all food safety regulations.

Application of GAG Sheet Blister

- Tray: It can be used for product turnover and inner support.

- Blister box: It can be directly used in the outer packaging of the product to enhance the sales competitiveness of the product. Common packaging methods are: card blister, heat sealing blister, high frequency blister, half-fold blister, three-fold blister and so on.

DESU is an excellent and professional thermoforming GAG plastic sheet manufacturer in China. Our factory is located in Shanghai, China. We have advanced production equipment, professional production technicians, and the product quality is stable and reliable. If you are looking for high quality GAG plastic sheets, you are welcome to contact us anytime.