With the continuous improvement of consumers’ living standards and the gradual change of consumption concepts, people have higher and higher requirements for the quality and safety of fresh meat. Maintaining the good freshness of fresh meat is not only related to food safety issues, but also to the sustainable development of the meat product industry. Therefore, how to extend the fresh-keeping period of refrigerated fresh meat has become a hot topic in industry research.

Packaging makes food more convenient for storage and transportation, provides greater safety assurance for food in terms of microbiological, biological and chemical changes, and extends the shelf life of packaged food. As the most intuitive feeling of consumers, in the past, meat products in supermarkets were mostly displayed to consumers in a naked form. Now, with the development of food-grade fresh supermarkets and the continuous improvement of the cold chain, more meat products are packaged in boxes and bags. Wait for the chilled meat in prepackaged form to show up. The change in this trend is because packaging fresh meat can delay the spoilage of fresh meat, reduce the loss of juice, and keep the color of the meat bright red.

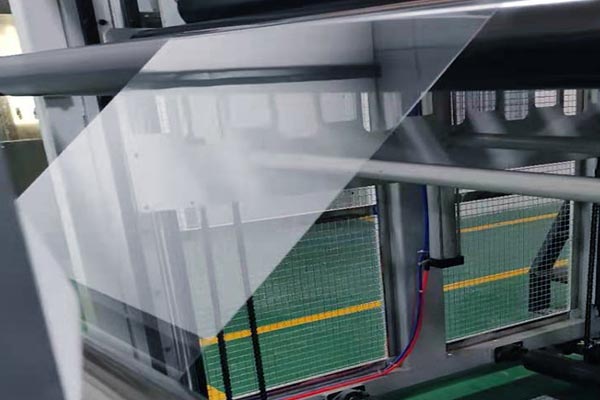

At present, the fresh-keeping packaging technologies for chilled meat mainly include vacuum packaging and fresh-keeping technology, modified atmosphere packaging and fresh-keeping technology, and a combination of various fresh-keeping technologies. Although the process is different, all of them can provide safety guarantee for the preservation of chilled meat. Among them, modified atmosphere packaging is a widely used method for preserving meat at this stage, especially in foreign countries. Modified atmosphere packaging is to replace the gas in the package with a gas suitable for food preservation. The commonly used gases are O2, N2 and CO2. The purpose is to inhibit the growth of microorganisms, slow down the oxidation reaction rate, and prevent enzymatic reactions, thereby extending the shelf life of products. The basic principle of modified atmosphere packaging for chilled fresh meat is to use high-barrier plastic sheets (plastic trays and lidding films) to make it difficult for outside air to enter the packaging. Modified atmosphere packaging can reduce the pressure of the product and the seepage of blood and water, and at the same time, a reasonable gas ratio is conducive to maintaining a good color of fresh meat.

PRT plastic for fresh food blister tray

Material: food grade PET plastic sheet

Specifications: 1410=14*10cm; 1414=14*14cm; 1911=19*11cm; 1813=18*13cm; 2410=24*10cm

Color: black, white, transparent

Application: suitable for packaging of fruits, vegetables, meat, fish, seafood, etc.

Features: Tough and practical, resistant to cold and heat, it is mostly used in fresh food stores/fruit stores/shopping malls/supermarkets to package fresh food. Used in combination with plastic wrap to ensure the freshness, hygiene, freshness and freshness of food.

Advantages: fresh-keeping, hygienic, reducing loss, simplifying the difficulty of purchasing, beautiful and high-grade, convenient transportation and distribution, and convenient and efficient packaging to beautify and add value to your fresh fruits and vegetables.

Advantages of PET sheet

1. It has good mechanical properties, the impact strength is 3-5 times that of other plastic sheets, and the folding resistance is good;

2. Resistance to oil, fat, enoic acid, dilute alkali, and most solvents;

3. Excellent high and low temperature resistance, long-term use is within 120℃, short-term use can withstand high temperature of 150℃, low temperature of -70℃, and high and low temperature have little effect on its mechanical properties;

4. Low gas and water vapor permeability, with excellent gas barrier, waterproof, oil-proof, and odor-proof performance;

5. High transparency, can block ultraviolet rays, good gloss;

6. It is non-toxic, tasteless, has good hygiene and safety, and can be directly used for food packaging.

DESU is a company specializing in R&D, production and sales of APET plastic sheet/roll, PET plastic sheet/roll, PET/PE plastic laminated sheet roll, PET ESD conductive sheet roll, coated PET sheet roll, PETG plastic sheet roll, black PET sheet roll, GAG plastic sheet roll, etc. Our company has 3 PET co-extrusion production lines imported from Germany and the United States, and 2 PET coating production lines imported from Germany, with an annual output of more than 10,000 tons. Products are mainly used in electronics, food, cosmetics, medical, hardware tools, printing and many other fields.