Specification

Product name: Antistatic PS Sheet Roll

Brand: DESU

Origin: Shanghai, China

Surface resistance: 109 to 1012Ω/sq

Width: 300-1400mm

Thickness: 0.2-2.0mm

Weight: 50-150kg/roll

Shape: Roll/Sheet

Color: Natural, Black, White, Color.

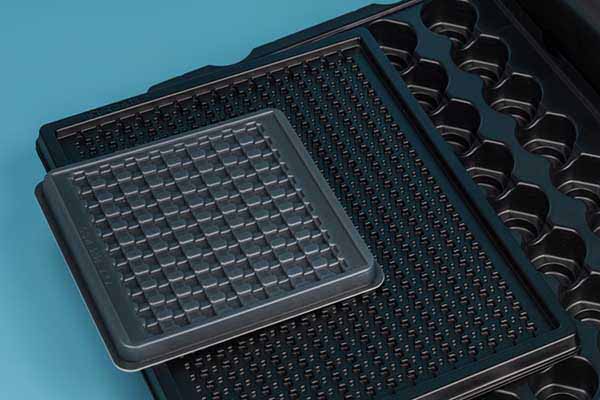

Molding Process: Vacuum forming

Introduction

Antistatic polystyrene packaging sheets are widely used in electronic product packaging due to their good rigidity, good processability and good dimensional stability of the finished product.

Physical and Chemical Properties

| Technical data | Test standard | Test value |

| Density | ASTM D-792 | 1.07G/cm3 |

| Yield tensile strength | ASTM D-638 | 25Mpa |

| Breaking Tensile Strain | ASTM D-638 | 48% |

| Impact strength | ASTM D-256 | 16KJ/m2 |

| Heat distortion temperature (cooling after heating) | ASTM D-648 | 81°C |

| Vicat softening temperature | ASTM D-1525 | 88°C |

| Surface resistance at 8%RH | ASTM D-257 | 109-11Ohm per square |

Antistatic Processing Method

Electronic products have high requirements for the antistatic performance of packaging materials, and static electricity is likely to be generated during the transportation of electronic products. If static electricity is not led away, it will cause great harm to electronic products. The antistatic polystyrene sheet can be obtained by applying an antistatic agent on the outside and adding an antistatic agent on the inside. The method of coating with antistatic agent is simple and has good antistatic effect and low material cost. However, the surface coated with antistatic agent is easy to fall off during transportation and use, causing the material to lose antistatic performance, and there are many such antistatic agents. It is an ionic surfactant, and its antistatic property is greatly affected by the environment, especially humidity and temperature. The antistatic agent added by the internally added antistatic agent includes two kinds of ordinary antistatic agent and polymer permanent antistatic agent. Compared with the externally coated antistatic method, the antistatic effect of the sheet obtained by the internally added antistatic agent method is long-lasting Better performance and less environmental sensitivity, but the material cost is relatively high, and the molding process requirements are relatively high.

ESD (electrostatic discharge) materials

| Material | Surface resistance (Ω/sq) | Characteristic |

| Conductive | 103 to 105 | Conductive materials have low resistance, so electrons can easily flow through the surface or inside of these materials. The charge will flow to the ground or another conductive object in contact with the material. |

| Static dissipation | 105 to 109 | Compared with conductive materials, static dissipative materials can make charge flow to the ground or other conductors in a more controlled and slow manner. |

| Anti-static | 109 to 1012 | Anti-static materials can inhibit friction and electricity generation. |

Application

Antistatic PS Sheet is mainly used for packaging of electronic and electrical products, such as pallets, outer boxes, etc.