Specification

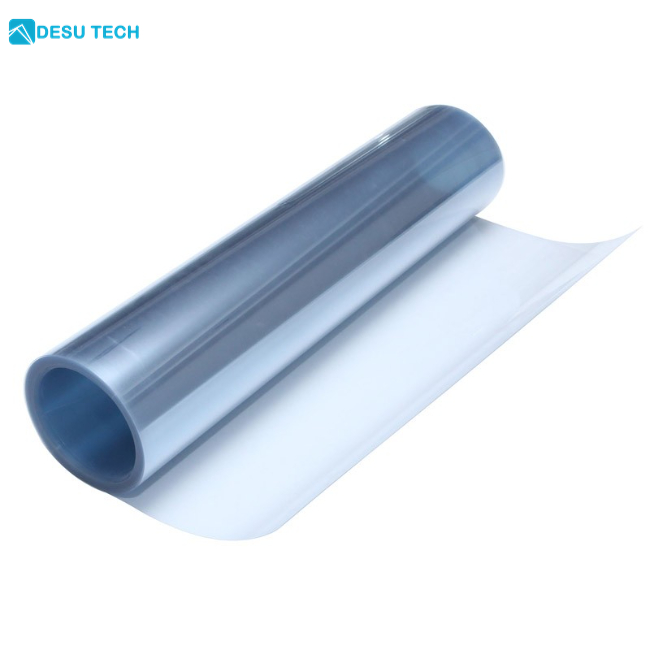

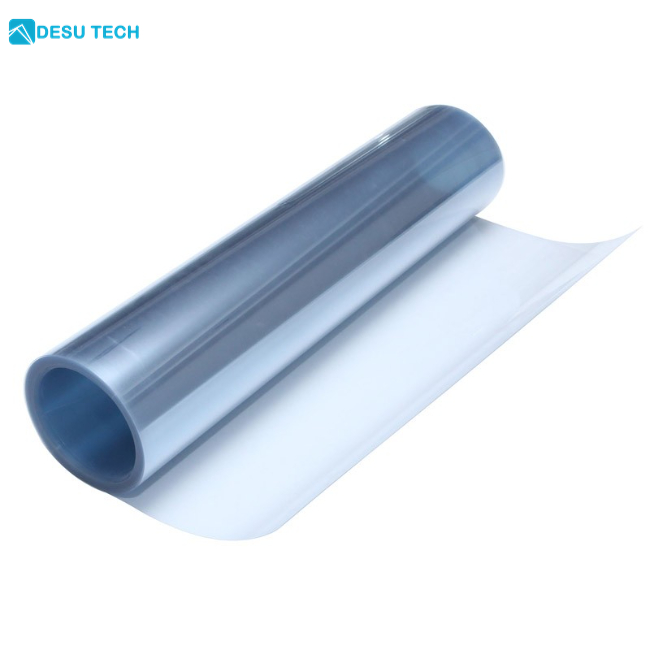

- Brand: DESU

- Origin: Shanghai, China

- Width: 300-1400mm

- Barrier material: Thermoforming Anti-fog PET Plastic Sheet

- Processing methods: Lamination / Multilayer co-extrusion

- Thickness: 0.2-2.0mm

- Weight: 50-150kg/roll

- Shape: Roll/Sheet

- Color: Clear

- MOQ: 5tons

Description Of Thermoforming Anti-fog PET Plastic Sheet

Thermoforming is a manufacturing process in which a sheet of plastic is heated and then formed into a specific shape by applying pressure. Thermoformed anti-fog PET plastic sheet is a plastic sheet that has been specially treated to prevent fogging on the surface.

During thermoforming, a thermoformed anti-fog PET plastic sheet is heated until it becomes soft and pliable. It is then placed on a mold and vacuumed into place, forming the desired shape. The sheet is then cooled and the plastic retains its shape.

Thermoformed anti-fog PET plastic sheet is a clear, lightweight and durable material commonly used in applications where clarity is critical, such as protective face shields commonly used in healthcare. Its anti-fog properties prevent condensation from forming on the surface, ensuring that medical personnel do not interfere with their vision while wearing it.

In addition to anti-fog properties, thermoformed anti-fog PET plastic sheets are also known for their resistance to impact, chemicals and UV radiation. It is a popular choice for thermoforming because of its ability to be easily shaped and molded into complex shapes.

Process Of Thermoforming Anti-fog PET Plastic Sheet

Thermoforming Anti-fog PET (polyethylene terephthalate) plastic sheet is a type of plastic sheet that has been specially treated to prevent fogging.

The process of thermoforming anti-fog PET plastic sheet typically involves the following steps:

1. Sheet Preparation: The anti-fog PET sheet is cut to the desired size and shape for thermoforming.

2. Heating: The sheet is heated until it reaches the appropriate temperature for thermoforming. This temperature may vary depending on the specific type and thickness of the PET sheet being used.

3. Forming: The heated sheet is then placed into a mold or forming tool and shaped into the desired shape using either vacuum forming or pressure forming techniques. In vacuum forming, the sheet is placed over a mold and a vacuum is used to suck the sheet onto the mold, while in pressure forming, the sheet is forced onto the mold with the use of compressed air.

4. Cooling: Once the sheet has been formed, it is cooled using either air or water. This helps to solidify the shape and ensure that it retains its form.

5. Trimming: Any excess material around the edges of the formed sheet is trimmed off to produce the final shape.

6. Quality Control: The final product is inspected to ensure that it meets the required specifications and quality standards.

Overall, the thermoforming process for anti-fog PET sheet involves heating, forming, cooling, trimming, and quality control to produce a high-quality, fog-resistant plastic product.

Features Of Thermoforming Anti-fog PET Plastic Sheet

Thermoforming anti-fog PET plastic sheet is a type of plastic material that is used in various applications such as packaging, medical devices, and consumer goods. It is characterized by several features that make it an ideal material for different purposes. Some of the features of thermoforming anti-fog PET plastic sheet include:

Anti-fog properties

This plastic sheet is designed to prevent fogging, which is important for applications such as packaging where clarity is essential. The anti-fog properties are achieved through the addition of special additives that prevent moisture from condensing on the surface of the sheet.

Clarity

Thermoforming anti-fog PET plastic sheet has excellent clarity, which makes it suitable for packaging applications where the product needs to be visible to the consumer.

Durability

This plastic sheet is durable and can withstand the rigors of handling, shipping, and storage without breaking or cracking. It is also resistant to impact and abrasion, which makes it an ideal material for applications that require toughness.

Chemical resistance

Thermoforming anti-fog PET plastic sheet is resistant to chemicals, including solvents, acids, and alkalis. This feature makes it ideal for use in medical devices and other applications where exposure to chemicals is a concern.

Recyclability

PET plastic sheet is recyclable, which makes it an environmentally friendly material. It can be recycled and used to produce other products, which reduces waste and conserves resources.

Parameter Of Thermoforming Anti-fog PET Plastic Sheet

| Origin | China |

| Markets | All over the world |

| Port | Shanghai / Ningbo |

| PET Shape | Roll / Sheet |

| Thickness | 0.18mm – 2mm |

| Width | 30mm – 1400mm |

| Color | Clear / Transparent / Custom Color |

| Free Sample | Free sample accepted |

| MOQ | 5 Tons minimum order quantity |

| Packing | Diameter≤38 inch PET Roll / 39 inch high Sheet |

| Delivery Time | 7 – 12 Days to delivery |

| Payment Accepted | D/A, D/P, TT, L/C, Westunion etc. |