Why do we choose anti-static PET plastic sheet and conductive PET plastic sheet instead of using cheap ordinary insulating PET? To understand this problem, it has to start with static electricity itself!

In simple terms, static electricity is a kind of electric atom, the micro-charge generated by the friction of objects with each other, which exists in space at any time. In spring and summer, due to the abundant rain and high humidity, the electric charge generated on the surface of the object will be brought to the ground by the water vapor along the skin or the surface of the object and disappear. However, in autumn and winter, because the surface of the object and the skin are relatively dry, once the generated electric charge encounters the opposite electric charge, an electric spark will be generated – that is, static electricity.

Since the surface resistance of ordinary PET is relatively high, generally above 1011, it is only suitable for use as an insulator. After understanding the generation principle of static electricity, we can understand why anti-static PET and conductive PET are used in electrical products (especially electronic components).

The purpose of using anti-static PET is to use the characteristics of anti-static PET and conductive PET to effectively eliminate sparks caused by electrostatic charges in electronic components, thereby minimizing potential risks. When electronic components are working, electrostatic sparks with different sizes of charges are generated due to the current running on the surface. When the electrostatic spark is small, the impact on electronic components is small, but when the electric spark accumulates to a certain extent, a strong instantaneous current will be generated, which will cause the circuit to catch fire or even explode.

About Conductive PET Plastic Sheet

There are generally two methods for the production of conductive PET sheet: One is to apply anti-static coating on the PET sheet. The antistatic PET sheet produced by this method is prone to damage the coating during storage and transportation, weakening the antistatic effect. The other is to add an antistatic agent to the base material during the production of PET sheets. The production cost of this method is higher, but the antistatic PRT sheet produced has a longer service life.

How anti-static PET plastic sheet and conductive PET sheet blister products achieve the function of eliminating static electricity:

1. Anti-static products refer to products with surface resistance value between 106-109 and surface voltage below 100V. (less than 106 is a conductor, more than 1011 is an insulator)

2. The working principle of anti-static PET is to keep the surface resistance value between 106-109 after special treatment of PET itself, so as to produce a uniform and thin layer of water vapor on the surface. When static electricity is generated inside the electronic components, the static electricity can be quickly conducted to the outside world through the water vapor layer on the surface of the anti-static PET to minimize the danger.

The basic physical properties of static electricity are:

(1) attract or repel.

(2) there is a potential difference with the earth.

(3) a discharge current will be generated.

These three properties can have three effects on electronic components:

(1) electrostatic adsorption of dust, reduce component insulation resistance (shorten life).

(2) electrostatic discharge damage, so that the components can not work due to damage (complete destruction).

(3) The heat generated by the electrostatic discharge electric field or current can damage the component (potential damage).

(4) The electromagnetic field generated by electrostatic discharge has a large amplitude (up to several hundred volts/meter) and a very wide spectrum (from tens of megabytes to several gigabytes), which can cause interference or even damage to electronic products (electromagnetic interference).

The characteristics of electrostatic damage to electronic products:

(1) concealment

The human body cannot directly sense static electricity unless an electrostatic discharge occurs. However, the human body may not feel electric shock when electrostatic discharge occurs. This is because the electrostatic discharge voltage perceived by the human body is 2-3KV, so static electricity is concealed.

(2) potential

After some electronic components are affected by static electricity, the performance does not decrease significantly, but multiple cumulative discharges will cause internal damage to the device and cause hidden dangers. Therefore, static electricity has the potential to damage the device.

(3) randomness

Under what circumstances will electronic components be damaged by static electricity? It can be said that from the time a component is produced until it is damaged, all processes are threatened by static electricity. The generation of these static electricity is also random, and its damage is also random.

(4) complexity

Due to the fine and tiny structural characteristics of electronic products, high-precision instruments such as scanning electron microscopes are sometimes required. But even so, some electrostatic damage failures are treated as other failures. Because ESD damage is often attributed to early failures or unexplained failures, the true cause is unwittingly masked before the damage is fully understood. Therefore, the analysis of electrostatic damage to electronic devices is complicated.

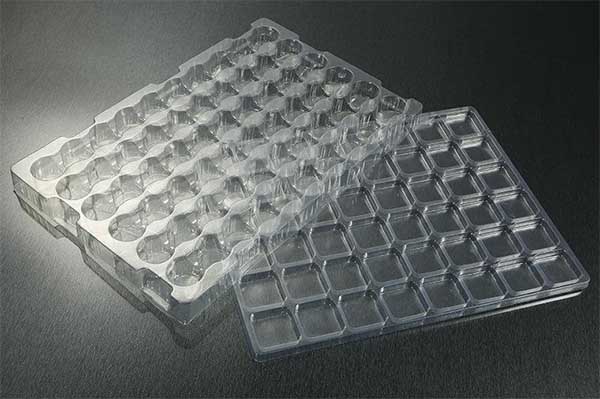

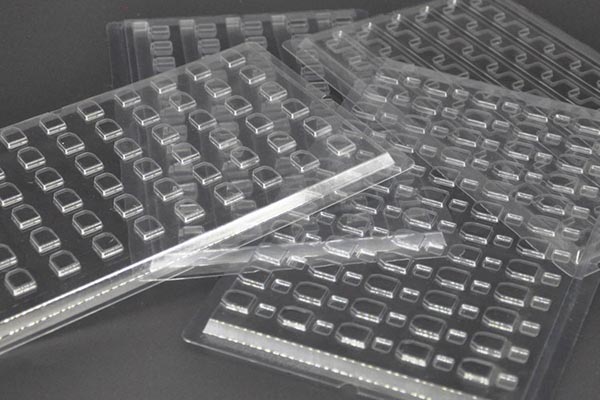

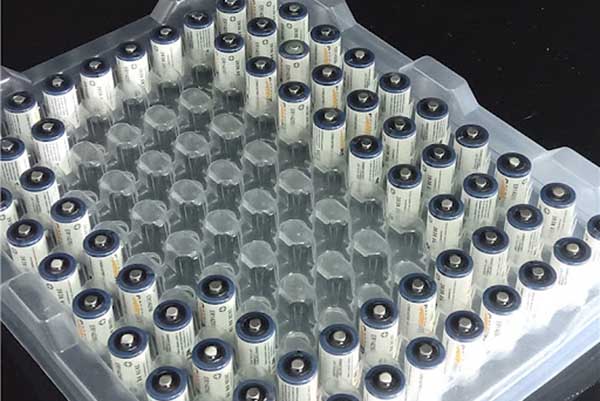

DESU is an excellent anti-static PET plastic sheet manufacturer in China. The anti-static PET sheets we produce can be used for thermoforming blister electronic trays for packaging, storage and transportation of electronic products, which can effectively prevent static electricity from damaging electronic products.