Blister packaging is everywhere in life. Food packaging, electronic product packaging, gift packaging, cosmetic packaging, etc. are all common blister packaging that are closely related to life.

Blister packaging: a general term for producing plastic products by a blister process and packaging the products with corresponding equipment.

What is blister?

A plastic processing technology, the main principle is that after heating and softening a flat plastic hard sheet (HIPS sheet, PET sheet, PVC sheet), it is vacuum adsorbed on the surface of the mold, and then formed after cooling. Plastic products with concave and convex shapes are widely used in plastic packaging, lighting, advertising, decoration and other industries.

Blister packaging products include: blister, tray, blister box. Synonyms are: vacuum cover, blister, etc.

The main advantages of blister packaging are that it saves raw and auxiliary materials, light weight, convenient transportation, good sealing performance, and meets the requirements of environmental protection and green packaging. It can pack any special-shaped products without additional buffer materials. The packaged products are transparent and visible, beautiful in appearance, easy to sell, and suitable for mechanized and automated packaging, which facilitates modern management, saves manpower and improves efficiency.

Types of blister raw materials:

1. PS plastic sheet has low density, poor toughness, easy to burn, and produces styrene gas (a harmful gas) when burning, so it is generally used to produce various industrial plastic trays.

2. PVC plastic sheet has moderate toughness and is not easy to burn. When burning, chlorine gas will be generated, which will have a certain impact on the environment. PVC is easy to heat and seal, and can be sealed by sealing machine and high-frequency machine. It is the main raw material for the production of transparent plastic products.

3. PET plastic sheet has good toughness, high transparency, easy to burn, does not produce harmful gas when burning, and belongs to environmental protection materials. But the price is high, suitable for high-end plastic products. The blister shells of European and American countries generally require the use of PET hard sheets, but it is not easy to heat seal, which brings great difficulties to packaging. In order to solve this problem, people use a material called PETG, which has both the heat-sealability of PVC and the high environmental protection and transparency of PET, but the price is higher.

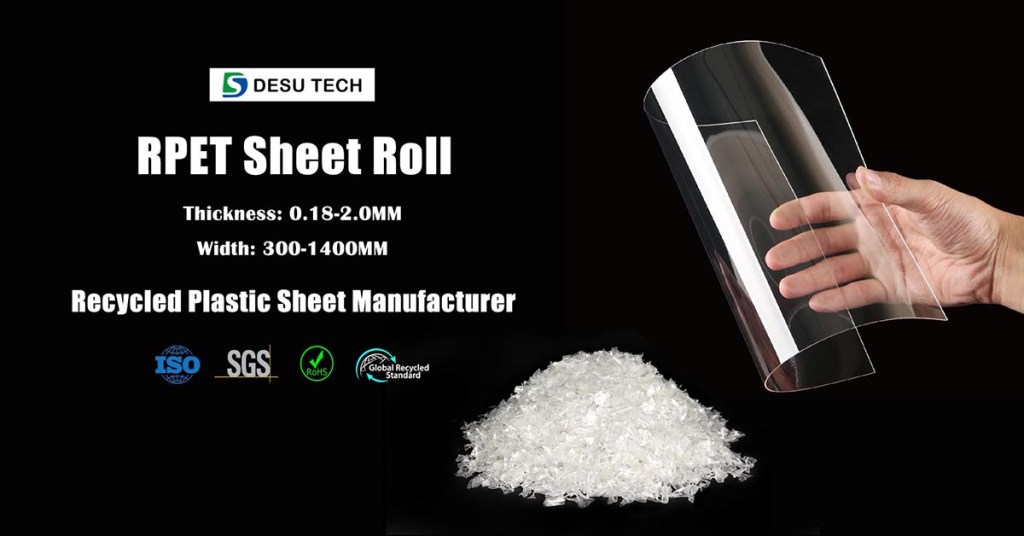

DESU is an excellent plastic sheet manufacturer in China, producing 0.2-2mm plastic sheets such as PP sheet roll, PET sheet, PS sheet, PVC sheet for thermoforming blister. We have more than ten years of production experience, and the plastic sheets we produce are of good quality and sell well all over the world.

If you need plastic sheets, please contact us immediately, you can get free samples, as well as competitive factory prices.