Raw material of PET sheet

Like other plastics, the properties of PET sheet are closely related to molecular mass. Intrinsic viscosity determines molecular mass. The greater the intrinsic viscosity, the better the physicochemical properties, but the poor fluidity makes molding difficult. The lower the intrinsic viscosity, the worse the physicochemical property and the worse the impact resistance. Therefore, the intrinsic viscosity of the PET transparent sheet should be 0.8dl/g-0.9dl/g.

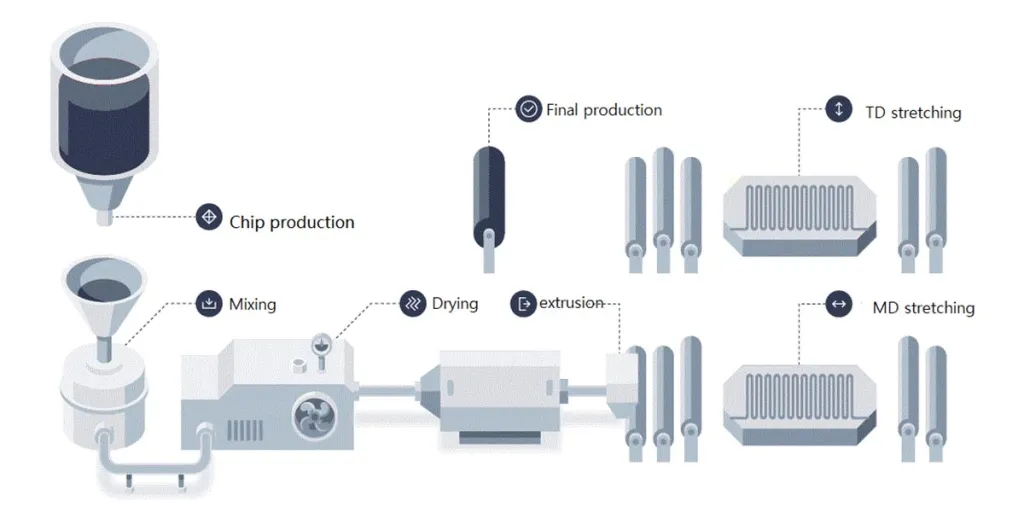

Production process

The main production equipment of PET transparent sheet is: crystallization tower-drying tower-extruder-die head-three roll burnishing machine-Roll up.

The production process is: crystallization of raw materials-drying-extrusion plasticization-extrusion molding-calendering and shaping-rolling.

Crystallization: The PET particles are heated and crystallized in the crystallization tower to make the molecules arranged neatly, and then the glass transition temperature of the particles is increased. The purpose is to prevent adhesion during the drying process and block the hopper. Crystallization is generally an indispensable step. The crystallization takes 30 minutes to 90 minutes, and the temperature is less than 149°C.

Drying: Under high temperature conditions, water can cause hydrolytic degradation of PET, resulting in a decrease in its Intrinsic viscosity, and its physical properties, especially impact strength, will decrease with the decrease of molecular mass. Therefore, PET must be dried before melt extrusion to reduce the moisture content, which should be less than 0.005%. Drying uses a desiccant dryer. Due to the hygroscopicity of the PET material, water will penetrate deep into the surface of the sheet to form molecular bonds, and another part of the moisture will exist deep inside the sheet, making it difficult to dry. Therefore, ordinary hot air cannot be used. The hot air dew point is required to be below -40℃, and the hot air is passed into the drying hopper through a closed loop for continuous drying.

Extrusion molding: After crystallization and drying, PET is transformed into a high polymer with obvious melting point. The molding temperature of high polymer is high and the temperature control range is narrow. A barrier screw dedicated to polyester is used to separate the unmelted pellets from the melt, which helps to maintain a longer shearing process and increase the output of the extruder. The flexible die lip die head with streamline baffle rods is adopted. The die lip is pointed and tapered. The streamline flow channel and the non-scratch die lip indicate that the smoothness should be good. The heater of the die head has the function of draining and cleaning. The die lip gap should ensure good uniformity, and the uniform die lip gap of the die directly affects the lateral thickness deviation of the sheet and the flatness of the calendering. When extruding into a sheet, the temperatures corresponding to the front area of the fuselage, the middle area of the fuselage, the rear area of the fuselage, the screen changer and the die head are 240℃-260℃, 265℃-275℃, 260℃-265℃, 260 ℃-265℃, 255℃-265℃.

Calendering: The melt enters the three-roll calender directly after coming out of the machine head for calendering and cooling. The distance between the three-roll calender and the machine head is generally about 8cm, because if the distance is too large, the sheet will easily sag And wrinkles occur, which leads to poor finish of the sheet. In addition, because the distance is too large, the heat dissipation and cooling are too slow, and the crystals become white, which is not conducive to calendering. The three-roller calendering unit consists of three rollers, the middle roller axis is fixed, and the temperature of the roller surface is 40℃-50℃ during cooling and calendering. The axis of the upper and lower rollers can be moved up and down, and the roller gap can be adjusted by moving the axis up and down. The temperature of the upper and lower rollers is 30℃-60℃ and 52℃-68℃ respectively. The three rollers should ensure the speed synchronization. Should be above the extrusion rate, the purpose is to offset the expansion of the material when it leaves the die and weaken the internal stress of the sheet, so that the wrinkles disappear. PET will crystallize in the range of 100℃-250℃, and the crystallization rate is 140℃-180℃ when the crystallization rate is faster, so the crystallization can be completed in a few seconds.

Rolling: The sheet comes out of the calender roller and enters the traction device by the guide roller. The components of the traction device are the active rubber roller and the passive rubber roller.

Common quality problems and solutions in PET transparent sheet production

The sheet material produces crystal point impurities:. the reason is due to the raw materials and scraps. The PET particles themselves will not produce crystal point impurities, but during the processing process, due to drying problems and more or less added scraps are introduced because of the bad environment Impurities or low-quality raw materials make it impossible to eliminate them during the sheet forming process.

Horizontal lines and water lines (orange peel lines).The water mark is because the material flow from the extruder die head enters the calender roll because there is no residual material between the calender rolls, so the sheet is not compacted, and the surface of the sheet exhibits a poor finish like orange peel. The lines. The solution is that there must be visible residual material between the calender rolls, and the residual material rotates evenly. The horizontal grain is the process defect of the extrusion method, just like the water ripple of the calendering method, the indentation caused by the speed difference between the two rollers of the calender roll, the solution is to require the three-roller calender The roller speed control accuracy is improved, and the synchronization accuracy must be improved to reduce the horizontal lines.

Sheet yellow, black spots or impurities, streamlines, uneven calendering, etc. The main reason for the occurrence of bubbles in the sheet is that the pellets are not completely dried and the water content exceeds 0.005%. If the water is not sufficiently dried, it will penetrate into the slice to indicate the formation of molecular bonds or remain deep inside the slice. If the drying temperature is too low or the time is too short, it will affect the drying effect. When blisters appear on the sheet, the drying temperature and time should be adjusted immediately. The main reason for the yellowing of the sheet is that the drying temperature is too high or the time is too long. At this time, the main measures are to lower the drying temperature and reduce the drying time. Another reason for the yellowing of the sheet is that the temperature of the melt is too high. At this time, the melt temperature should be reduced quickly. The main reason for the black spots and impurities in the sheet is that the filter screen is broken or the PET decomposition material remains in the extruder.

The main points of PET transparent sheet production

1.The primary conditions for the production of PET transparent sheets are the drying time and the control of the hot air dew point. The drying effect directly determines the physical and mechanical properties and production of the sheet. Attention should be paid to the control of drying temperature and time when drying. The drying temperature and time can neither be too high nor too low. If the dew point cannot be lowered, check the molecular sieve. The aging molecular sieve cannot absorb the moisture in the air and cannot achieve the purpose of drying the slice. At this time, the molecular sieve must be replaced.

2.If the temperature of the melt exceeds 280°C, the PET sheet will be discolored or decomposed, so the melt temperature must be controlled below 280°C.

3.The die lip gap of the die head determines the flatness and thickness uniformity of the sheet. The three-roller temperature plays a key role in the transparency of the sheet and indicates the smoothness. The PET melt needs to quickly avoid the temperature zone with the fastest crystallization rate, and instantly change from the melting temperature. It drops below the crystallization temperature, so the distance between the die and the calender roll is particularly important.