EVOH is one of the three major barrier resins that are currently industrially produced. It is a new type of polymer material that integrates the processing of ethylene polymers and the gas barrier properties of vinyl alcohol polymers.

Because EVOH resin has excellent barrier properties to many gases, it is often used in the food industry as the inner layer of multilayer food packaging films. Because there is no need to add plasticizer, it will not make the contents stale, and has excellent hygienic properties, non-toxic, odorless, and has good processability, heat resistance and recyclability. EVOH has an increasingly important position in the field of food, pharmaceutical and other commodity packaging.

EVOH not only has good barrier properties to gases, solvents, etc., but also has excellent oil resistance and organic solvent resistance. Its antistatic performance is excellent, and it can also be regenerated, free of chlorine and dioxin, and it is a green and environmentally friendly product. As a barrier material with excellent performance, it can be widely used in various types of packaging. The disadvantage is that the barrier performance of EVOH is greatly affected by the environment. When the humidity is > 60%, the barrier performance decreases significantly.

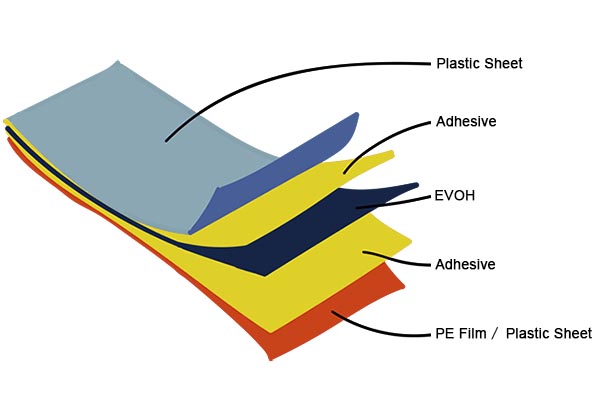

Since EVOH is hydrophilic, its gas barrier properties are affected by humidity, which hinders the expansion of its application range. Therefore, EVOH is mostly used to manufacture the intermediate layer of composite packaging materials, and is used in combination with other materials with good moisture resistance. Such as EVOH/polypropylene (PP), EVOH/polyethylene terephthalate (PET), etc.

Compounded with polyolefin

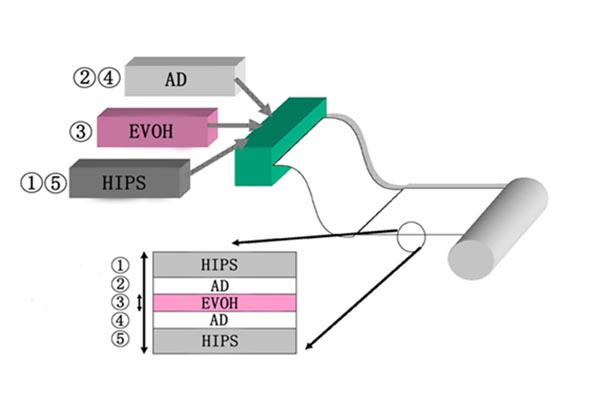

Since EVOH is hygroscopic, and its barrier property will be greatly reduced with the increase of humidity, in order to prevent EVOH from affecting its barrier property due to moisture absorption, it is usually compounded with polyolefin with good water resistance to form a multi-layer co-extruded composite film. Its typical structure There are low density polyethylene (LDPE)/EVOH/LDPE, LDPE/EVOH/ethylene-vinyl acetate copolymer (EVA), PP/EVOH/PP, etc.

EVOH Barrier Plastic Composite Sheet

Compounded with Nylon (PA)

EVOH and PA have a very good affinity, can be mixed in any proportion, and have excellent adhesion, and there is no need for an adhesive layer between the two layers during co-extrusion. For EVOH, it can be combined with PA to make a strong and tough composite film. For PA, it is easy to produce residual deformation during heating and molding, and it is difficult to maintain the molding shape. After compounding with EVOH, it can better meet the requirements of molding processing due to its high glass transition temperature. Its representative structures are: PA/EVOH/EVA, PA/EVOH/LDPE, PA/EVOH/LDPE, polypropylene (PE)/PA/EVOH/PA/PE, etc.

Considerations for choosing an adhesive

The edge material produced by the PP/EVOH co-extruded sheet cannot be mixed into the coating layer PP, otherwise it will increase the moisture permeability of the PP layer, thereby affecting the high barrier properties of the EVOH layer, and it cannot be mixed into the EVOH layer. The edge material of the extruded sheet should be crushed and then co-extruded, that is, in the composite sheet, add a layer of return material between the outer layer of PP and the adhesive, or use the EVOH/PP edge material for other purposes.

PP and EVOH cannot be thermally bonded, and an adhesive must be used between PP and EVOH. The adhesive is based on polyolefin, and its bonding mechanism is to bond with the PP layer by entanglement of the molecular chains of the substrate. The connection with EVOH is that the polar group of the adhesive forms a chemical bond with the OH group of EVOH.

When using the adhesive, attention should be paid to: (1) Choose the adhesive with PP as the base material. (2) The matching of melt viscosity between adhesive and PP and EVOH should be considered. (3) The tensile properties of the adhesive should be considered to avoid delamination during secondary processing.

EVOH composite packaging container product introduction

EVOH+PP co-extrusion blow-molded bottle has good transparency, can clearly display the shape and color of the content, can meet the long-term sterilization needs of food and other products below 120 ℃, can be heated by microwave, widely used in canned fruit and vegetable, jam Packaging in the fields of seasoning, milk, fast food soup, etc.

EVOH+PE material has an opaque structure. After adding color masterbatch, it can be processed into finished products of different colors. It can also be processed into black color separately in the recycling layer to reduce the influence of light on the content. The PE-based resin has excellent processing performance and volume. There is no limit to the size, super complex and super large containers can be blow-molded and can be sterilized for a long time at 85 °C. , pesticides, automotive fuel tanks and other chemical materials packaging.

EVOH+PET material has excellent transparency. Generally, PET bottles can only withstand the sterilization temperature below 68 °C, but can withstand 95 °C sterilization after being blown and shaped by a high-temperature blow molding machine (the bottle mouth needs to be crystallized), and it is light in weight. , Easy to carry, no special tools are required to open the bottle, and it is widely used in the packaging of beer, wine, juice, milk and other fields.

EVOH complies with the development trend of plastic sheet for food packaging

(1) For most of the new packaging, raw materials based on petrochemical products will be mainly used.

(2) Further development of aseptic packaging will reduce the need for refrigeration equipment.

(3) More and more consumers are willing to use plastic cans and bottles, which will replace glass and, in some cases, metal.

(4) Flexible packaging materials are developing towards high quality.

(5) Reduce packaging costs by improving the performance of packaging materials, rather than unilaterally pursuing material price reductions. (Packages are different from general products and require frequent loading, packaging, storage, transportation and other commodity processes. Customers often have a process of storage and use after purchasing, so the quality of packaging must be guaranteed and improved)

(6) Lightweight packaging will continue to make progress.