Since PP is a high polymer with a CH structure and contains up to 90% of C, it is a flammable high polymer. At the same time, PP is also an excellent insulator of electricity, and it is easy to generate static electricity. The resulting fires and explosions occur from time to time, so some special-purpose PP must be treated with antistatic and flame retardant.

Flame retardant PP resin is divided into different flame retardant specifications such as UL94 V0, UL94 V1, UL94 V2 and UL94 HB according to the flame retardant grade. Compared with ordinary plastics, flame-retardant plastic products can greatly reduce the risk of fire in the event of short circuit, overload, flooding, etc. It is mainly used in the field of home appliances, such as coil skeletons, plug-in board shells, small home appliance parts, microwave ovens, refrigerators, washing machines, electrical and electronic products and other flame retardant components.

The flame retardant PP sheet is formed by adding flame retardant to the PP raw material by heating and extrusion. PP sheet is widely used in UV and silk screen printing industry, stationery and gift industry, medicine and health industry, packaging industry, food industry, lighting industry, electronics industry and so on.

Application of Flame Retardant PP Sheet in Lithium Batteries and Lithium Batteries

Application 1: The technical field of ion batteries – insulating gaskets for steel shell cylindrical batteries

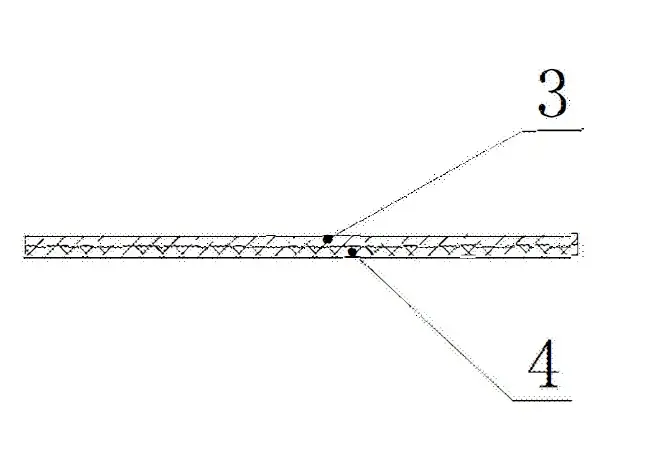

It is characterized in that it consists of two-layer structure, including A side and B side, and A side and B side are circular. The A side is a PP layer with a thickness of 0.5~1.0mm, and the B side is a non-woven layer with a thickness of 0.5~1mm.

The center of the A surface is provided with a central circular hole of the A surface, and the edge of the A surface is provided with an edge circular hole or a strip hole. The center of the B surface is provided with a central circular hole of the B surface, and the diameter of the central circular hole of the B surface is the same as the diameter of the central circular hole of the A surface. The diameter of the edge circular hole is half of the diameter of the central circular hole on the A surface, and the number of the edge circular holes is eight.

It can prevent the battery cap from being polluted by the splash of electrolyte due to extrusion and the collision of the sealing die during the sealing process, and has a good protective effect on the rust of the steel shell cylindrical battery cap.

Application 2: The field of ion battery technology – the separator of lithium battery pack

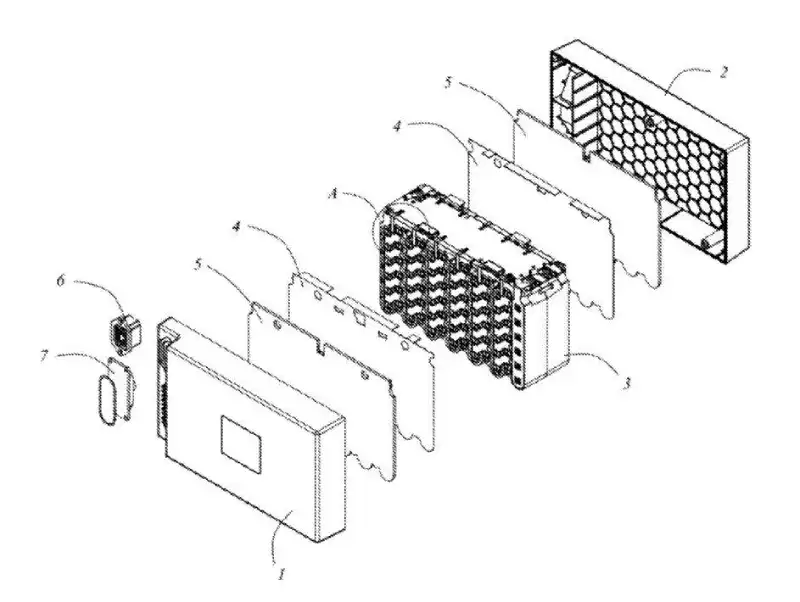

A lithium battery pack structure for an electric vehicle comprises an upper cover assembly, a lower cover assembly and a battery assembly (3)’ located between the upper cover assembly and the lower cover assembly.

The battery assembly (3) includes a plastic bracket and several columns of battery cells (33) mounted on the plastic bracket.

The battery cell (33) has two columns, which are respectively the output end of the positive electrode and the output end of the negative electrode of the battery assembly (3).

The cells (33) described in other columns are connected in series between the negative pole of the cell (33) serving as the positive output end, and the positive pole of the cell (33) serving as the negative output end.

The cells (33) described in several columns are connected to the control board (31) arranged on the plastic bracket.

A PP film (4)’ having an insulating effect is provided on both the positive electrode and the negative electrode of the battery cell (33). A foam (5) for shock absorption is arranged on the PP film (4).