Specification

- Product name: High Transparency Conductive PET Sheet Roll

- Brand: DESU

- Origin: Shanghai, China

- Surface resistance: 103 to 105Ω/sq

- Performance: Permanent/Semi-permanent Conductive

- Width: 300~400mm

- Thickness: 0.18~2.0mm

- Weight: 50~150kg/roll

- Shape: Roll/Sheet

- Color: Clear

ESD (electrostatic discharge) materials

| Material | Surface resistance (Ω/sq) | Characteristic |

| Conductive | 103 to 105 | Conductive materials have low resistance, so electrons can easily flow through the surface or inside of these materials. The charge will flow to the ground or another conductive object in contact with the material. |

| Static dissipation | 105 to 109 | Compared with conductive materials, static dissipative materials can make charge flow to the ground or other conductors in a more controlled and slow manner. |

| Anti-static | 109 to 1012 | Anti-static materials can inhibit friction and electricity generation. |

Introduction

The permanent conductive PET plastic sheet can handle the static electricity outside the electronic components. For the electronic components with circuit board components, the conductive sheet can ensure that all the components are in the stable condition of the same electric potential.

Characteristic

1.Can achieve high transparency (substrate + surface coating);

2.Excellent electrical conductivity;

3.The conductivity is stable and does not change with temperature and humidity;

4.It is environmentally friendly and can be recycled.

Why should we choose antistatic or conductive PET sheet

Static electricity is a kind of electric atom generated by friction between objects, and it exists in the air at any time. In the rainy season, due to the high humidity in the air, the charge generated on the surface of the object will be carried to the ground by water vapor and disappear. But in the dry season, because the surface of the object is relatively dry, once the generated charge encounters the opposite charge, it will generate electric spark-static electricity. Due to the relatively high surface resistance of PET sheets, it is necessary to use antistatic or conductive pet materials on electrical products.

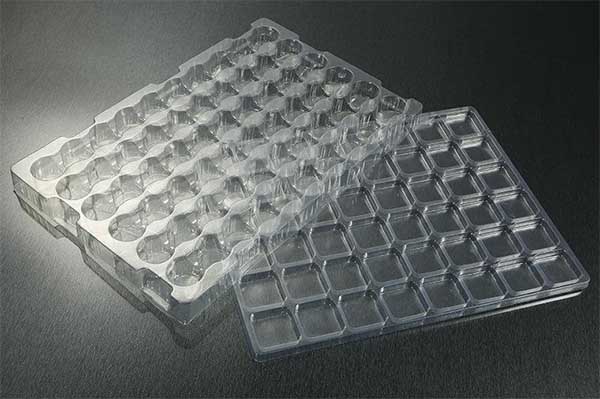

Applications

- Hard Disk Manufacturing

Today’s hard disk manufacturing industry has the most sophisticated and sensitive electronic components in the electronics industry, which require clean and continuous ESD protection. This product is used for the packaging, turnover and storage of hard disk heads and other precision components;

- Semiconductor manufacturing

The semiconductor industry has more stringent requirements for cleanliness than ESD protection in the process of handling wafers and disk drive media. As IC circuits continue to shrink, ESD protection is becoming more and more important. This product is used in the turnover and storage of chips and disk drive media;

- Electronic product assembly and packaging

Since electronic products have already received a lot of ESD protection before they are assembled and packaged, in general, the requirements for ESD can be slightly reduced, and permanent static dissipation performance is required. This product is used to handle and transport electronic components, circuit boards and other components.

Conductive PET sheet is widely used in electronic product packaging