Specification

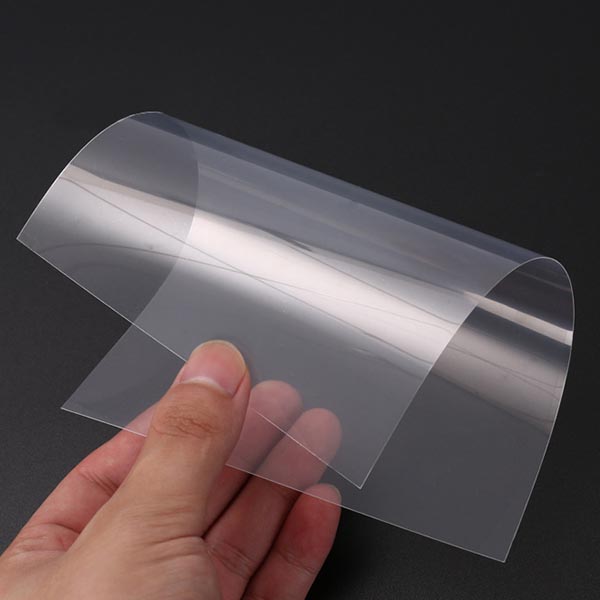

- Product name: 0.5mm clear thin PETG plastic sheet

- Brand: DESU

- Origin: Shanghai, China

- Width: 300~1400mm

- Thickness: 0.18~2.0mm

- Weight: 50~150kg/roll

- Shape: Roll/Sheet

- Color: clear, white, green, blue, orange, brownetc, etc.

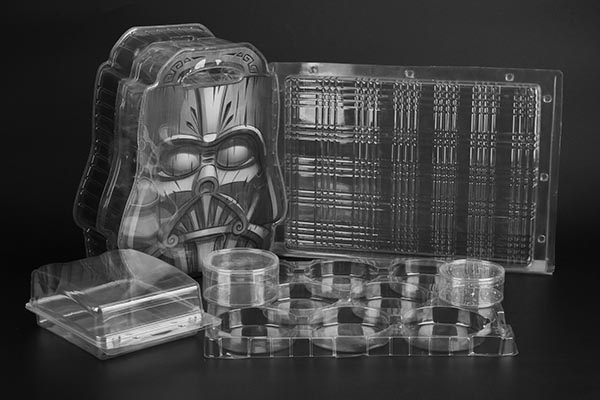

- Application: Thermoforming vacuum blister

Polyethylene terephthalate, commonly referred to as PETG or PET-G, is a thermoplastic polyester with outstanding chemical resistance, durability, and excellent manufacturing formability. Due to the low forming temperature, PETG can be easily vacuum formed and pressure formed as well as heat bent. Additionally, PETG is well suited for manufacturing techniques such as die cutting, routing and bending.

PETG plastic sheet is a food safe plastic that is FDA food safe. Commonly used in the manufacture of food containers and liquid beverage bottles and other kitchen items. Like acrylic and many other thermoplastics, PETG is fully recyclable.

Application of PETG plastic sheet

PETG has a variety of uses due to its ease of thermoforming and chemical resistance. It is commonly used in single-use and reusable drinking bottles, edible oil containers, and FDA-compliant food storage containers.

PETG plastic sheet thermoformed blister packaging is often the material of choice for supermarket stands and other retail product displays.

At the same time, PETG also exists in the medical field, where its rigid structure allows it to withstand harsh sterilization processes, making it the perfect material for medical implants as well as the packaging of pharmaceuticals and medical devices.

PETG is less prone to cracking than acrylic (plexiglass). PETG plastic sheets are used to vacuum form a wide variety of transparent plastic products – especially blister food trays and clamshell packaging as well as medical device packaging, among others.

The advantages of PETG plastic sheet:

- High transparency, good gloss, smooth surface, not easy to deform.

- Strong viscosity, good barrier property and waterproof.

- Stress-free whitening, folding resistance.

- Good chemical stability, not easy to corrode, good fire resistance.

- Resist low temperature embrittlement

- Has good aging resistance and reliable insulation.

- Highly UV stable, good mechanical properties, high hardness and strength.

What is the difference between PETG and PET?

Although PETG looks similar to PET, they are different materials at the molecular level. PET is the result of the combination of two monomers. PETG may involve these same monomers, but also include ethylene glycol, giving it a different chemistry than PET. PETG is less brittle and more flexible than other PET equivalents, making it ideal for bottles. PETG has better shock resistance and is more suitable for higher temperatures.