ABOUT THIS CUSTOMER

This UK customer contacted us through our official website. At first, he didn’t know what type of plastic sheet he needed.

After communication, we learned that this British customer is a food company, and he needs to buy some food packaging trays to pack the food they produce.

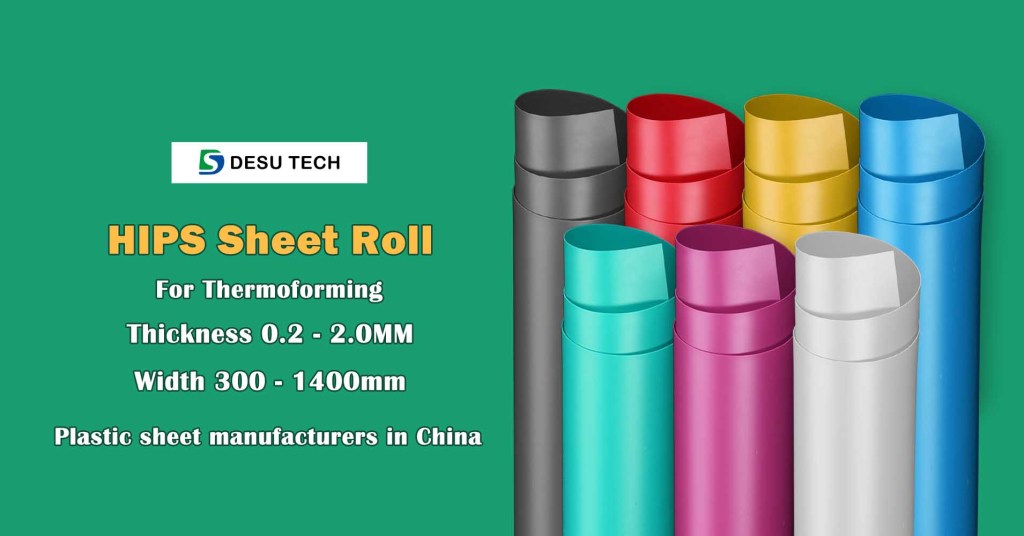

According to his needs, we recommended HIPS plastic sheet rolls for him, which are very suitable for use in food packaging.

HIPS plastic sheet rolls have the advantages of high chemical resistance, high heat resistance, good barrier properties, light weight, and easy processing. In addition, HIPS plastic sheet rolls are also recyclable, which protects the environment while creating economic benefits. It is in line with the business philosophy of the client company.

HIPS PLASTIC SHEET ROLLS ADVANTAGE

Low static electricity generation, suitable for packaging products that require low static electricity.

Easy to vacuum forming, and the product has good anti-attack performance.

It has good hygiene and can directly contact with food without producing harmful substances.

Easy to color processing can be processed into different colors to produce sheets of different colors.

Good hardness, this kind of sheet material has better hardness than other sheet materials of the same thickness. After thermoforming, it can be used as a hot and cold drink cup.

It meets environmental protection requirements and can be recycled and reused. When its waste is incinerated, it does not produce harmful substances that harm the environment.

READY FOR DELIVERY

After the customer pays, we start to hurry up the production. Today, we will pack the PP plastic sheet roll ordered by the customer and send it to the customer.

In order to ensure that customers can process and produce after receiving our products, we package each roll of products in a certified way to avoid damage during transportation.

Step 1: second-rate PE protective film.

Step 2: On the outside PE film, it will be wrapped with aluminum foil, which has great functions of heat insulation, waterproof and anti-scratch.

Step 3: Each layer of material rolls will be separated by cardboard to prevent collisions.

Step 4: The shipping label indicates the product specifications, and the QR code can trace the source of product production information.

Guarantee the quality of each batch of goods.

Step 5: The outer layer is wrapped with cardboard and wrapped with film to prevent the outer packaging from being scratched and collided.

Step 6: The top of each pallet will be covered with cardboard, and the bottom is a fumigation-free wooden pallet.

Other plastic sheet recommendations