Thermoforming plastic sheet is a widely used packaging material. The plastic sheet is heated to a flexible molding temperature, formed into a specific shape in a mold, and trimmed to produce a usable product. When it comes to thinner gauges and certain material types, the sheet is heated in an oven to a high enough temperature so that it can be stretched onto the mold and cooled to its final shape. Its simplified version is vacuum forming, which is used in mass production.

PET Sheet

Hard, good toughness, high strength, bright surface, environmentally friendly and non-toxic, transparent and multi-color sheets. The disadvantage is that it is more difficult to heat PET with high frequency, and the price is much higher than that of PVC.

PP Sheet

The material is particularly soft, good toughness, environmentally friendly, non-toxic, and high temperature resistant. It is often used as packaging for dining utensils or other high temperature resistant products; but its plasticity is poor, processing is difficult, surface gloss is poor, and the color changes during processing shallow.

PS Sheet

Low density (light weight), environmentally friendly, non-toxic, very good plasticity, poor toughness and brittleness, and can not be made into transparent materials, so it can only be made into base blister, because it is easy to crack, this kind of blister is not suitable for recycling

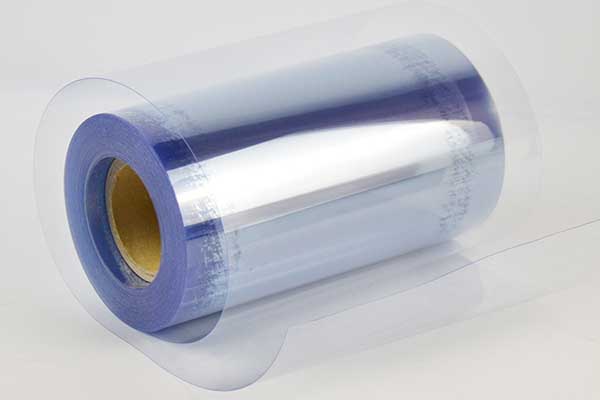

PVC Sheet

The most commonly used blister material, soft, strong, and malleable. It can be made into transparent and various colors. Transparent PVC is commonly used for packaging electronics, cosmetics, toys, gifts and other products.